HIGH SHEAR SCREEN

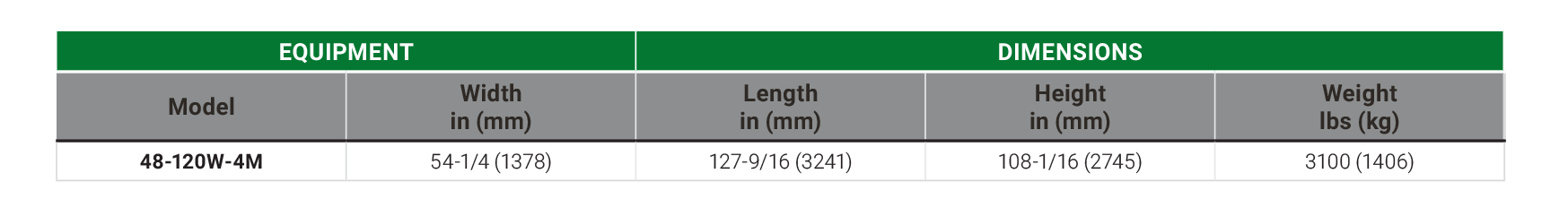

Derrick Corporation wet screening machines include a specialized unit for processing light, flaky, hard to convey solids. The Derrick Model 48-120W-4M High Shear Screener is a custom designed, open single-deck machine that can be operated in both non-hazardous and hazardous environments. This machine is typically used in wet sizing applications as fine as 325 mesh (45 microns) using Derrick Polyweb® urethane screens for kaolin clay, mica and fly ash.

FEATURES & BENEFITS

- Low sound production

- Easy screen inspection, removal and installation

- Light-weight screen panels for easy installation

- 304 Stainless steel construction option

- 37.5 degree machine angle with screen panel sections set at multiple downhill angles promoting thin, uniform slurry layer for positive conveyance of light and plate-like particles

- Wash water spray bar system

- Abrasion resistant bonded rubber lining option for feeder and discharge hoppers

- Abrasion resistant urethane exterior coating option for vibrating screen frame and discharge hopper lining

- Open design allows visual inspection of screen panels

- Convex crown promotes consistent screen panel tension, increases screen panel life

- Perpendicular-to-flow screen panel tensioning allows for use of Derrick Polyweb urethane and traditional wire screen panels

- Rubber float mounts effectively isolate support frame from vibration of screen frame

- Rapid change draw bolt/draw bar assemblies provides fast and easy screen panel changes

- Derrick Polyweb urethane screens as fine as 325 mesh (45 microns) and traditional wire screens produce efficient fines removal from 40 mesh (425 microns) to 400 mesh (38 microns)

- Zero maintenance

- E3 vibratory motor promotes positive conveyance of oversize particles

- Powerful, quiet and low energy consumption

- Greased-for-life bearings

RELATED DOCUMENTS

High Shear Screener

Fill out the form below to Download Brochure: