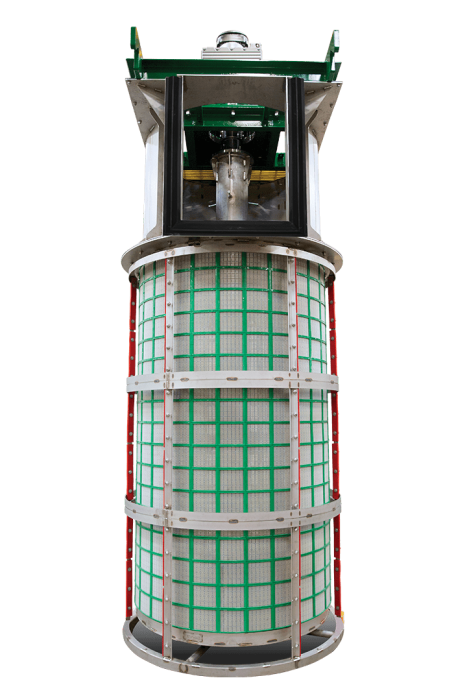

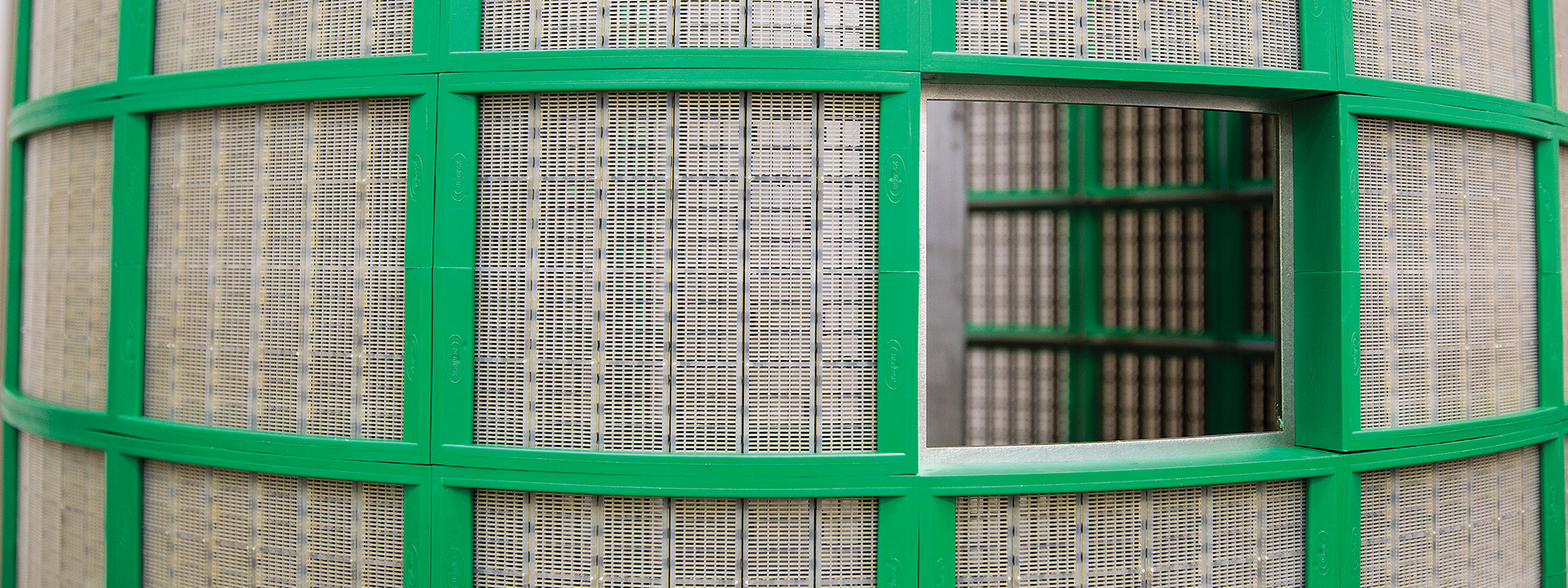

Prioritizing HSE, Derrick has focused the G-Vault design on operator safety, utilizing a compression seal drain on the bottom of the unit, eliminating unnecessary moving parts. An optional draft tube, operating on a standalone drive system accessible from the top of the unit, can be incorporated for pumping applications. Additionally, each screen on the G-Vault unit can be easily removed while connected to the launder due to its modular design – all of which lead to a reduction in working under suspended loads.