SUPERCHARGED SCREENING. SUPERSTACK SUPERSTACK

SuperStack®

Derrick Corporation has once again redefined high capacity, high efficiency, fine particle wet screening with the introduction of the SuperStack®. With 8 decks operating in parallel and innovative Front-to-Back (FTB) tensioning system, the SuperStack has a demonstrated capacity up to 3 times that of the best fine screens currently available.

- 8-Decks

- Front-to-Back (FTB) Tensioning System

- Up to 3 Times the Capacity of the Best Fine Screens Currently Available

All of this added capacity comes with only a slight increase in the space required per machine, significantly reducing the total capital and installation cost as well as OPEX for any screening installation.

SuperStack

Features & Benefits

Flo-Divider™

- Equalizes feed flow from source(s) to each deck for optimal separation efficiency

- Dart valves allow flow to be stopped to one or more outlets

Feeders

- Urethane pockets built into each feeder distribute feed slurry uniformly across the entire width of the screen

- Easily removed front cover facilitates maintenance and debris removal

- Interior lining options available for different feed characteristics

Derrick Intergrated Vibratory Motors

- Less than 80dB sound production and rated for continuous-duty operation

- Internal oil lubrication system provides many years of maintenance-free operation

Repulp Spray System

- Increase screening efficiency without increasing deck length

- Spray bars designed to dispense water into repulp wash troughs

- Added free water helps undersize material pass through screen panels

- Replaceable rubber repulp wash troughs

Screen Decks

- Screen beds crowned in the direction of flow rather than side to side, resulting in increased capacity with more effective utilization of the entire screen width

- Time required to replace screen panels is significantly reduced with innovative Front-to-Back (FTB) screen panel tensioning system

- Robust design with abrasionresistant urethane screen frame coating for extended useful life

- Accepts Derrick long-life, highopen-area, anti-blinding Polyweb®. urethane screen surfaces

- Unique, patented technology available only from Derrick

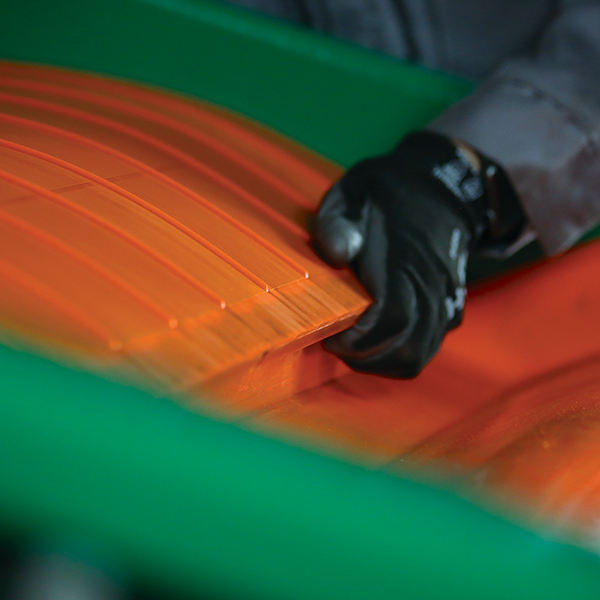

Polyweb Urethane Screen Panels

- Full range of Polyweb urethane screen panels with apertures ranging from 53 micron to 6.2mm

- Specialized formulations to cope with various temperature and chemical environments

- Unique non-blinding design for optimal efficiency and capacity

- Long lasting—commonly 4 to 12 months

- Long slot and short slot designs with up to 45 percent open area

Optional Oversize Launder Vibrators

- Dual oversize launders (one per side)

- Oversize conveyance assisted by push water or optional vibrators

- Easily accessible for inspection and maintenance

Featured

Documents

Case Study 246

ArcelorMittal Nippon Steel India

- Derrick SuperStack reduces ultra fines, improves blaine number, and increases the life of one of Asia’s longest continuous slurry pipelines

Case Study 248

Kropz South Africa

- Emerging phosphate rock producer saves millions on infrastructure costs with high-capacity Derrick SuperStack

Global Mining Review

Fine Margins

- During the last few decades, the fine coal cleaning circuit has been widely accepted due to technological advancements in size classification technology, coal-ash separation, dewatering, process control, etc.

Discover More About the

Derrick SuperStack

Contact a Derrick representative for more information!