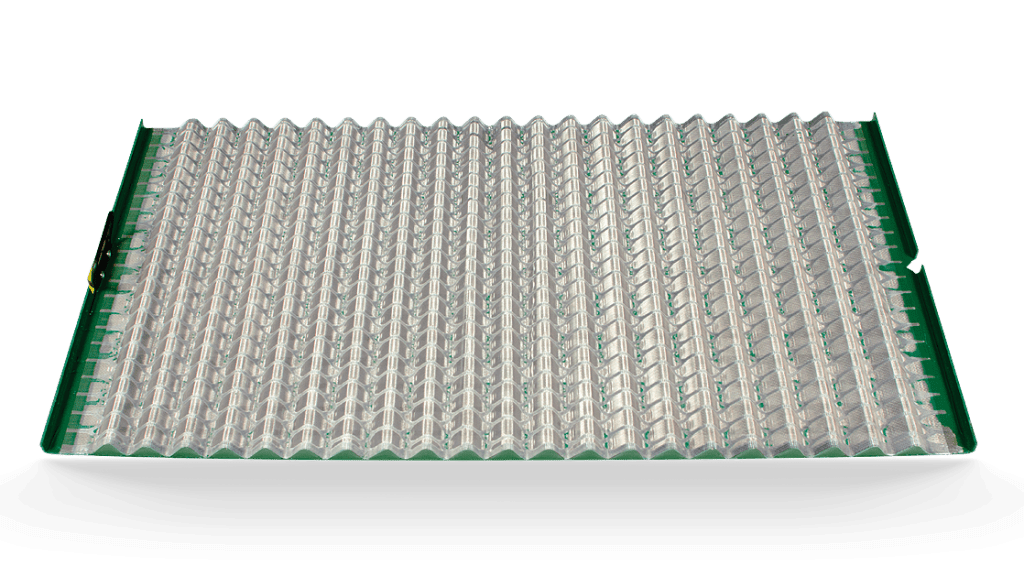

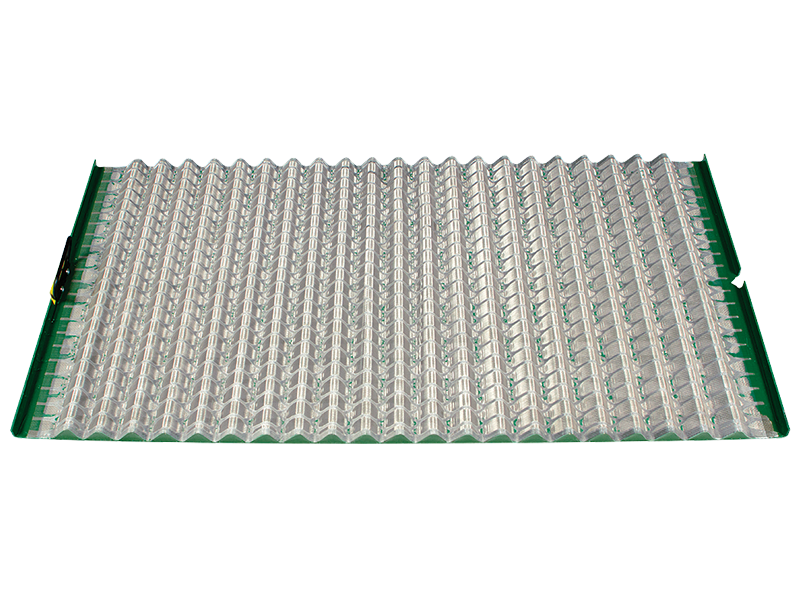

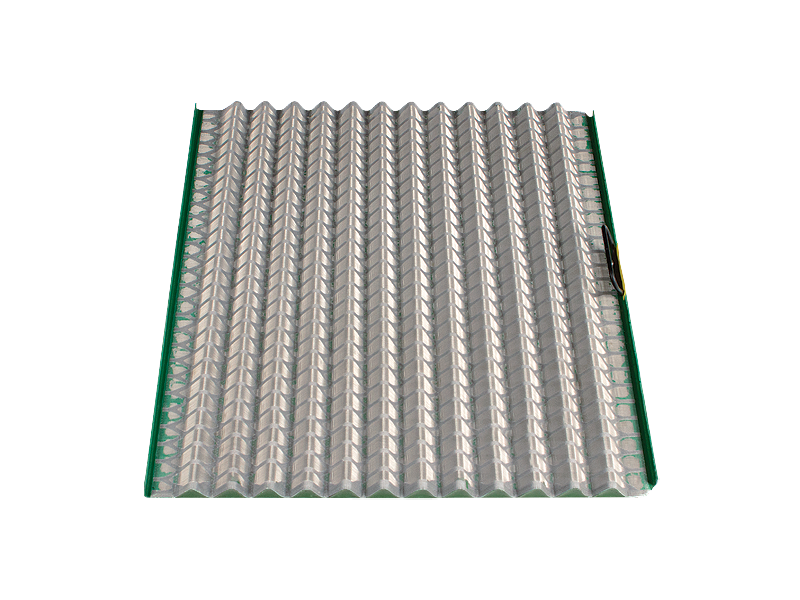

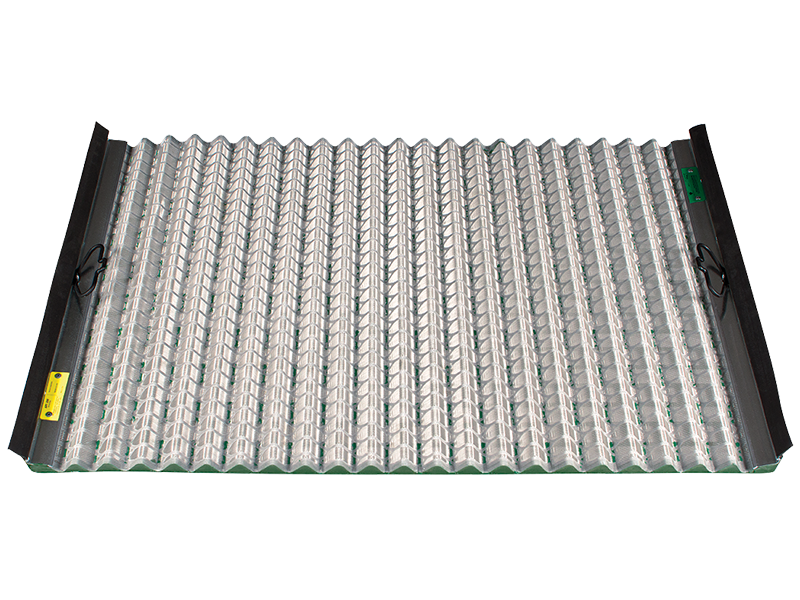

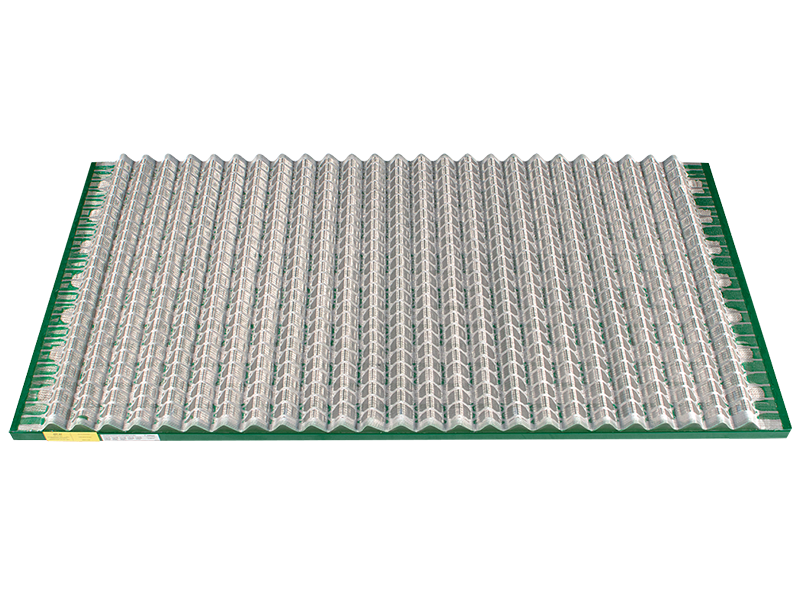

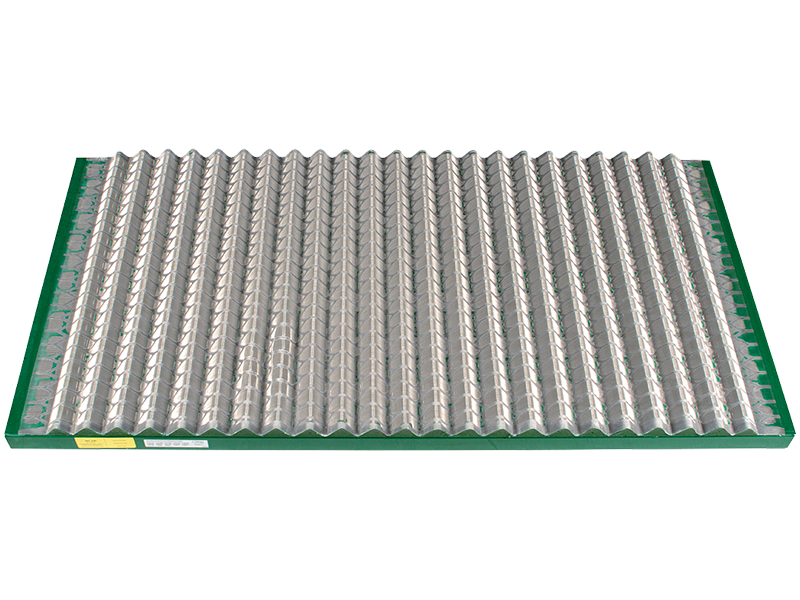

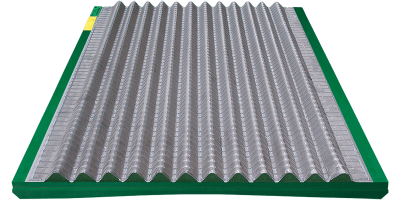

Derrick has revolutionized screening technology with the patented Pyramid® (PMD®) and Pyramid Plus™ (PMD+™) screens. These revolutionary three-dimensional screens offer the benefits of traditional flat multi-layered screens while adding a significant increase in usable screen area. The result is a screen that increases fluid handling capacity. Pyramid and Pyramid Plus screens provide an easy, cost effective increase in shaker performance. Designed with the latest technology, Pyramid screens allow rigs to screen finer earlier in the drilling process, thus significantly reducing mud and disposal costs. All Derrick screens are API RP 13C compliant.