CIVIL CONSTRUCTION

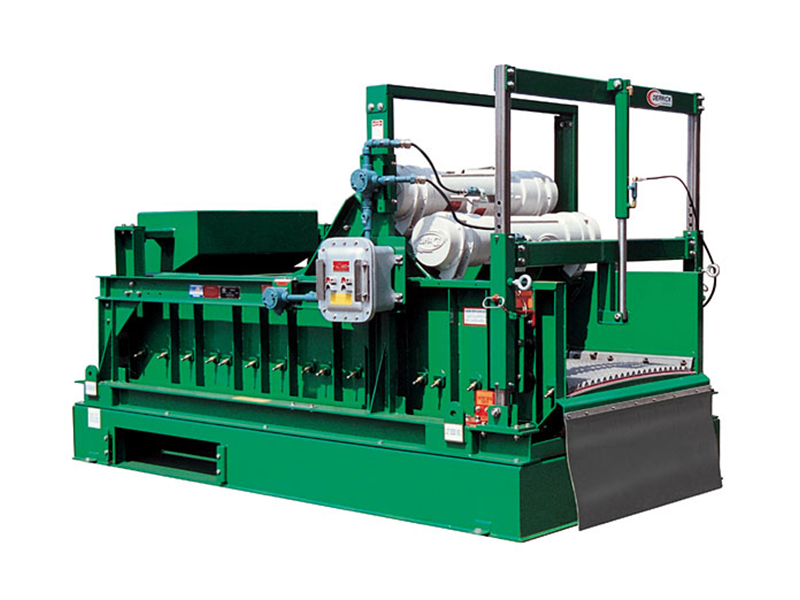

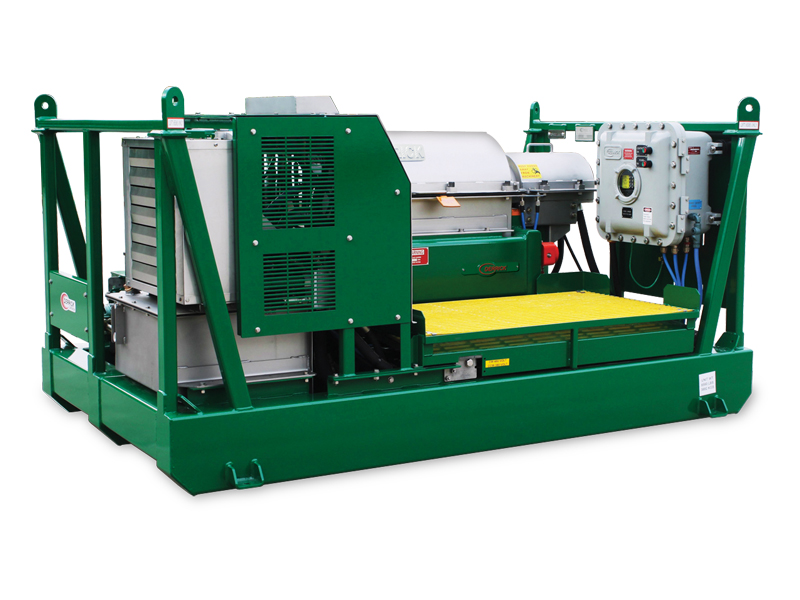

Since 1988, Derrick has manufactured innovative technologies for the Civil Construction industry. Derrick’s separation technology offers unmatched solids removal performance. Using this equipment and innovative screen technology, customers continuously recycle and re-use drilling fluid, while also controlling drilled solids and impact on the environment. Derrick offers premium slurry separation and desanding equipment to the worldwide Horizontal Directional Drilling, Microtunneling, Large Diameter Tunneling, Hydrovac Mud Processing, Slurry Wall/Foundation Drilling, Water Well Drilling, and other civil construction industries. Our civil construction solutions are currently used worldwide by companies that require high-efficiency separation and slurry dewatering in environmentally sensitive and urban environments.

Let Us Find The Right Product For Your Application.

EXCLUSIVE BENEFITS

- High capacity fine screening

- Increased solids control removal within a smaller environmental footprint

- Reduced non-production time

- Reduced hauling and disposal of solids-laden drilling fluid

- Lower water usage and hauling

- Decreased wear on downstream pumps, plumbing, and other equipment

- Increased operational performance within a smaller environmental footprint

RELATED DOCUMENTS

Solids Control for Civil Construction

Fill out the form below to Download Brochure:

Case Study 300 – Derrick® Mini Separation System and DE-7200™ VFD™ optimize cutter soil mixing technology project

Fill out the form below to Download Case Study:

Case Study 301 – Derrick® Modular Slurry Separation Plant maintains maximum microtunneling production

Fill out the form below to Download Case Study:

Case Study 302 – Derrick® Modular Slurry Separation Plant provides optimal slurry separation for a Northeast contractor

Fill out the form below to Download Case Study:

Case Study 303 – Derrick® provides increased production at reduced costs to Colorado contractor

Fill out the form below to Download Case Study:

Case Study 304 – Derrick® greatly enhances solids removal in Portland microtunneling project

Fill out the form below to Download Case Study:

Case Study 305 – Midwestern contractor selects Derrick® HI-Cap™ shaker for pile drilling project

Fill out the form below to Download Case Study:

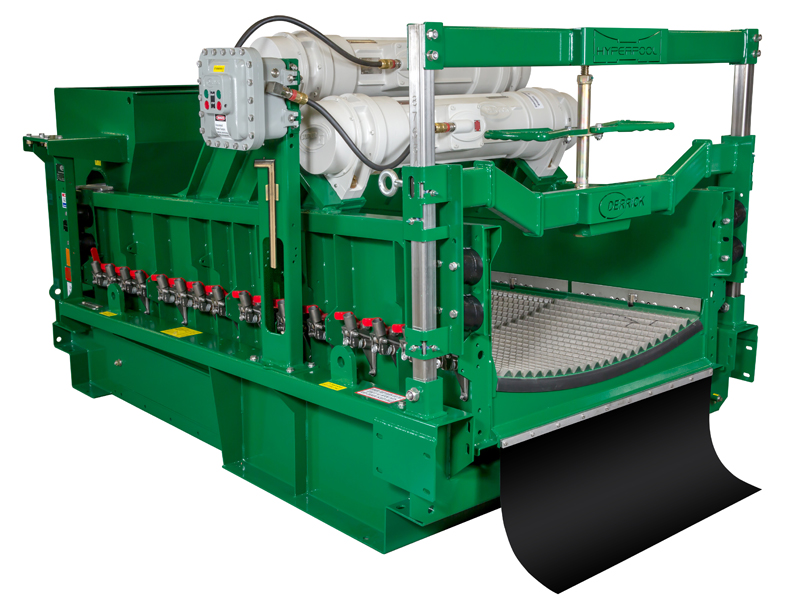

Case Study 308 – Upgrading to Derrick® Hyperpool® shakers and Pyramid® screen technology allows for a more cost effective HDD drilling program

Fill out the form below to Download Case Study:

Case Study 309 – Flowtex S.A. Breaks HDD Crossing Record with Hyperpool Technology

Fill out the form below to Download Case Study:

Case Study 310 – Hyperpool® shaker and Pyramid® screen technology reduce haul off costs and improve downhole production for HDD Contractor

Fill out the form below to Download Case Study:

Case Study 311 – Derrick Hyperpool® vs. Competitor Shaker

Fill out the form below to Download Case Study:

Case Study 312 – Derrick Hyperpool® vs. Competitor’s Double Deck Shaker

Fill out the form below to Download Case Study: