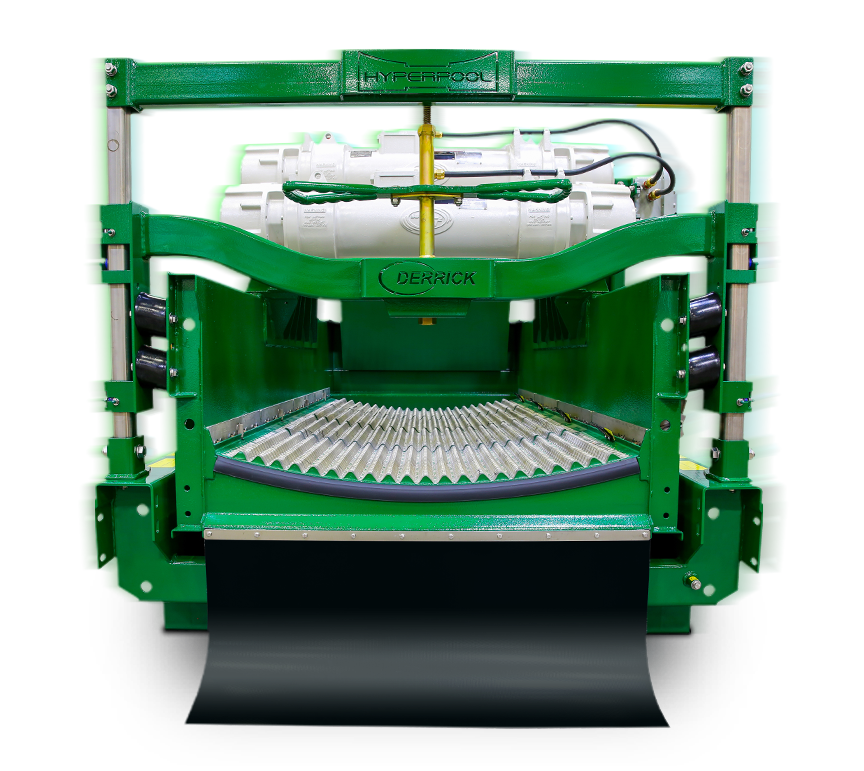

Backed by over 60 years of cost-effective solutions plus award-winning service, the Derrick Hyperpool® shaker is the latest in a long line of products designed expressly to exceed the demanding needs of today’s oilfield drilling operations.

With its compact footprint, industry-leading processing capacity, solids bypass prevention, and low maintenance cost, the Hyperpool is well suited for all drilling applications where drilling performance and rig modularity are required. The Hyperpool is designed to bring maximum value to the customer.

Founded by H. William Derrick Jr. in 1951, Derrick Corporation was created to solve some of the most challenging mechanical separation needs of the Mining Industry. At the heart of our present-day offering resides the Integrated Vibratory Motor which was invented by our founder and gave life to an entire line of innovative separation technology. To this day, our pioneering spirit pulses through the organization and inspires development of our leading-edge solutions.