DE-1000™ FHD™ DUAL VOLTAGE

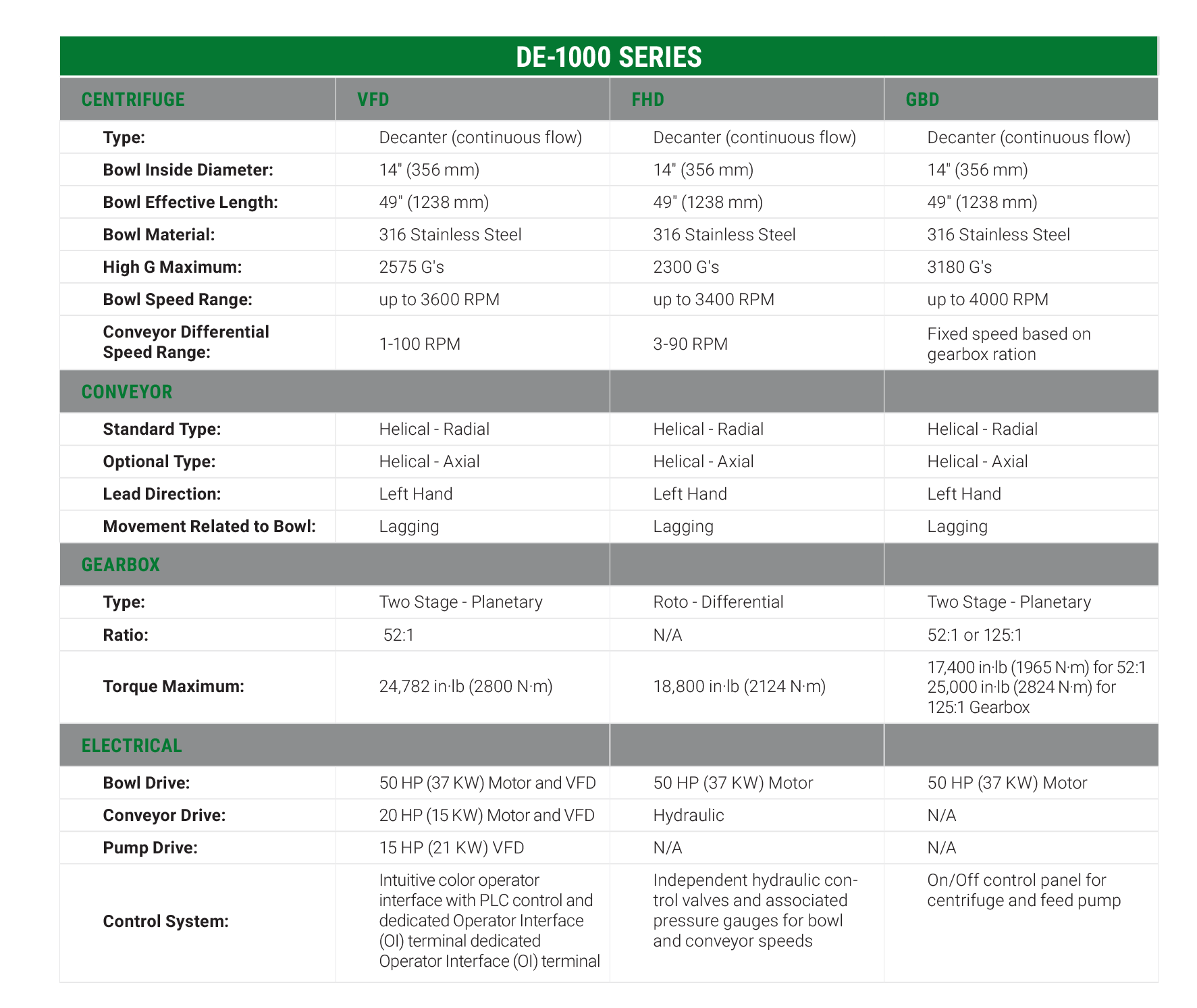

Operating at bowl speeds from 0 to 3400 RPM, with internal centrifugal acceleration exceeding 2300 G’s, the DE-1000™ Full Hydraulic Drive (FHD™) centrifuge can process 20 pounds per gallon of weighted mud, as well as flocculated ultra-fine solids slurries. A self-contained hydraulic system supplies pressure to the hydraulic motors that drive the bowl and the differential conveyor that operates at 3 to 90 RPM. Continuous monitoring of feed characteristics is used for automatic conveyor boost and protects the machine from overloads. The FHD centrifuge is designed for minimal maintenance and may be used in Class I, Division 1, Group C and D areas. Its stainless steel bowl and hardened conveyor tiles ensure long life and minimal maintenance.

FEATURES & BENEFITS

- Driven by a 50 HP motor, the bowl attains up to 2300 G’s at 3400 RPM to separate fine solids at high feed rates

- 18,800 in-lbs maximum conveyor torque with Rotodiff hydrostatic conveyor drive

- Independent adjustment of bowl speed and conveyor differential speed for optimal performance

- Automatic feed pump cycling and conveyor boost reduce the likelihood of rotating assembly overload and associated operational downtime

- Automatic safety shutdown for hydraulic fluid high temperature, high pressure, or low fluid level

- Capable of operating on 440V/3phase and 460V/3phase at 60Hz or 380V/3phase and 415V/3phase at 50Hz without any loss in performance

- Can be deployed around the world without changing electrical components or motors

† Centrifuge Bowl Cover Open

RELATED DOCUMENTS

DE-Series Centrifuges

Fill out the form below to Download Brochure:

Case Study 302 – Derrick® Modular Slurry Separation Plant provides optimal slurry separation for a Northeast contractor

Fill out the form below to Download Case Study: