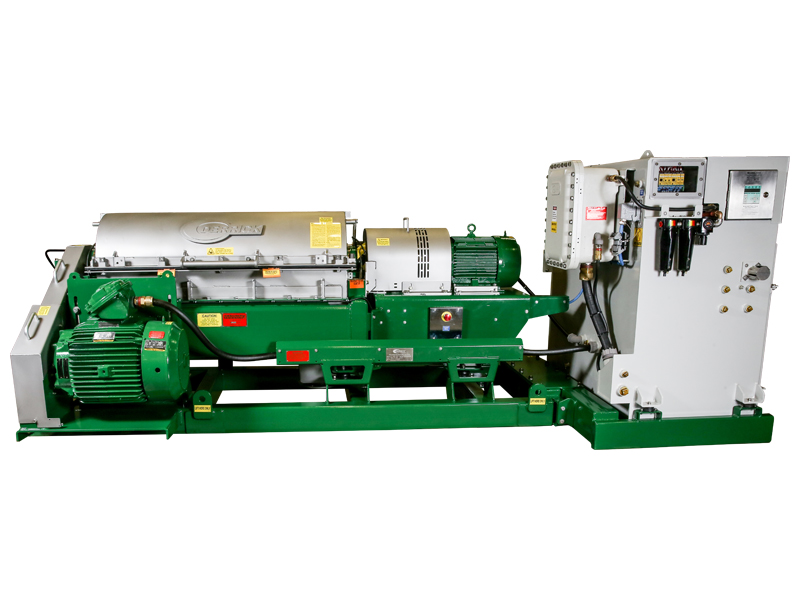

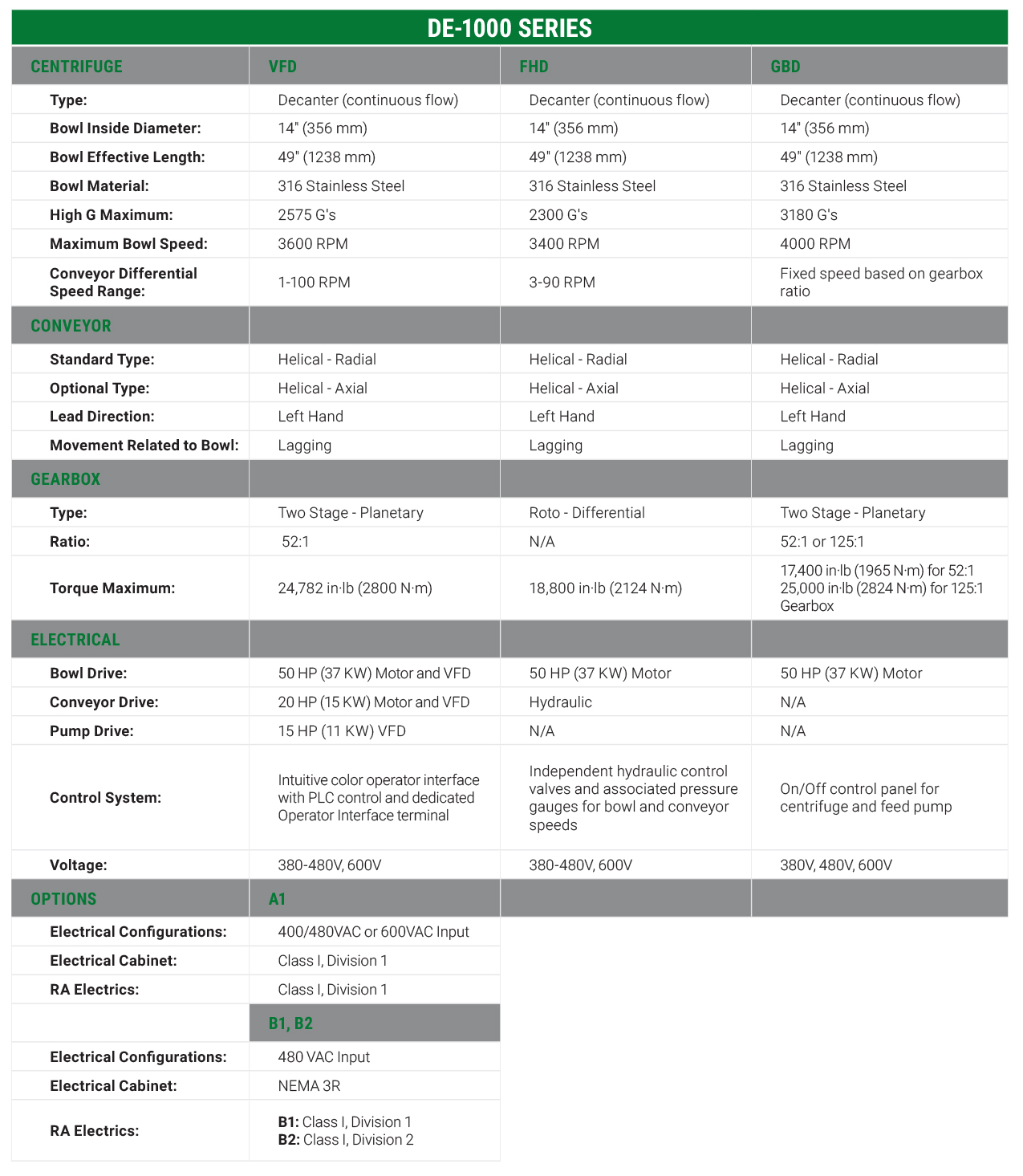

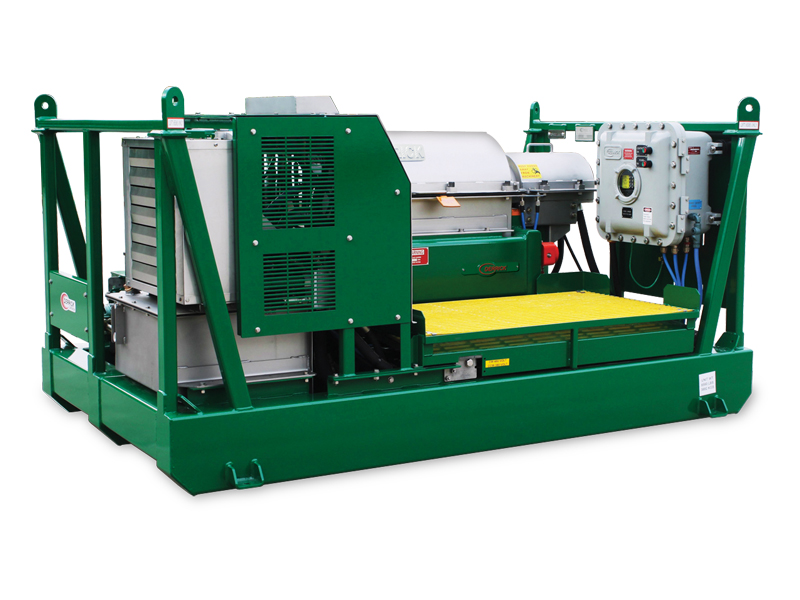

DE-1000™ LP VFD™ DUAL VOLTAGE

Combining the field-proven durability of the DE-1000™ series rotating assembly with the same state-of-the-art control system as on the DE-7200™, the DE-1000 LP (Low Profile) VFD™ is Derrick’s premium small bowl centrifuge offering. With PLC-controlled variable frequency drives controlling bowl and conveyor speed as well as feed rate, the DE-1000 LP VFD can be rapidly optimized for most efficient solids control in a wide range of drilling applications. The automated control system adjusts feed rate based on centrifuge loading, ensuring the maximum solids removal without operator intervention. The DE-1000 VFD may also be controlled and monitored from a safe location offsite, protecting personnel from hazardous conditions onsite and allowing remotely located experts to assist in operation and maintenance. The Low Profile (LP) is a modular design, allowing the control cabinet to be positioned separately from the centrifuge for the safety of equipment operators and increased flexibility for job site installations.

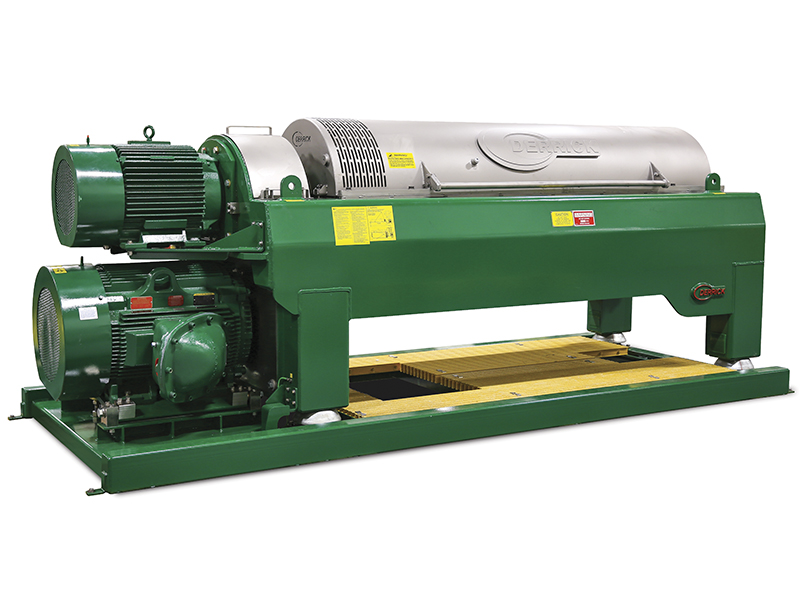

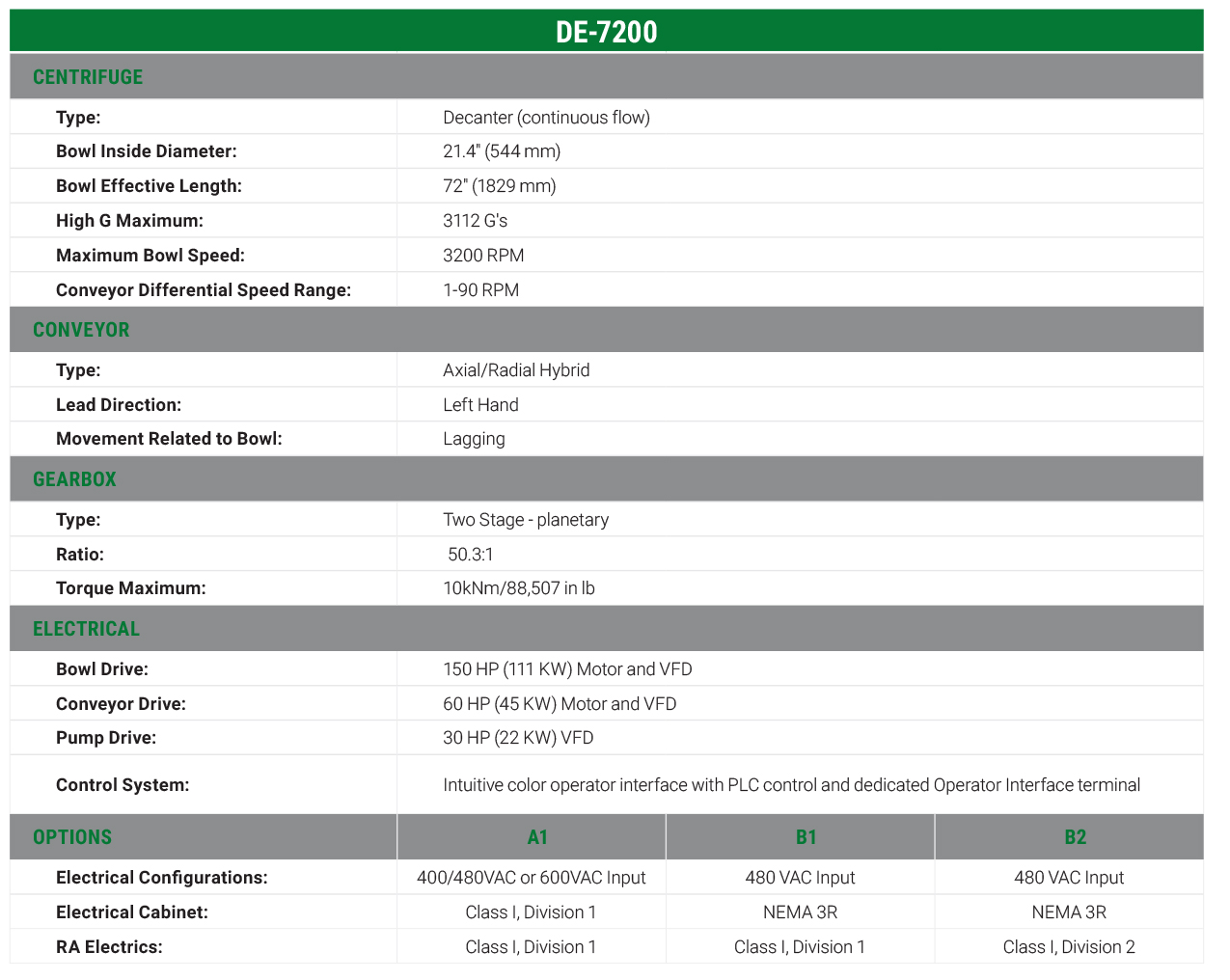

DE-7200™ VFD CENTRIFUGE

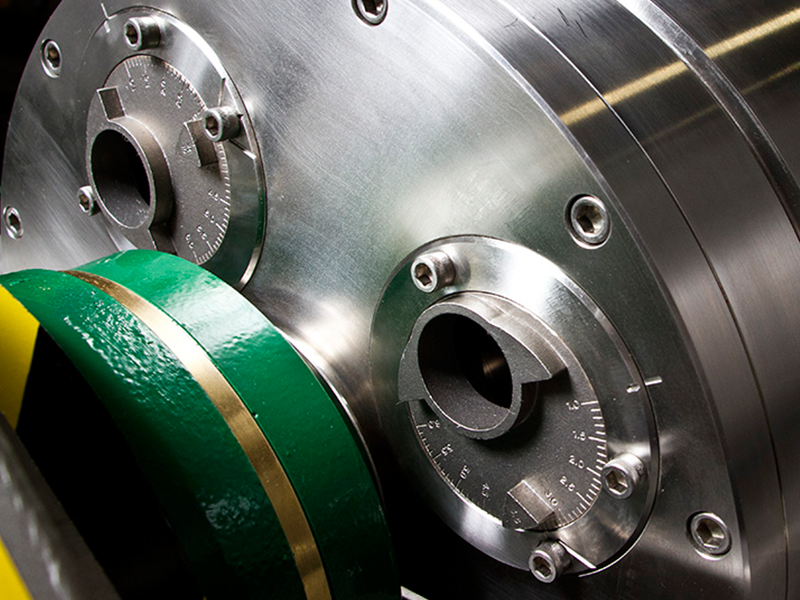

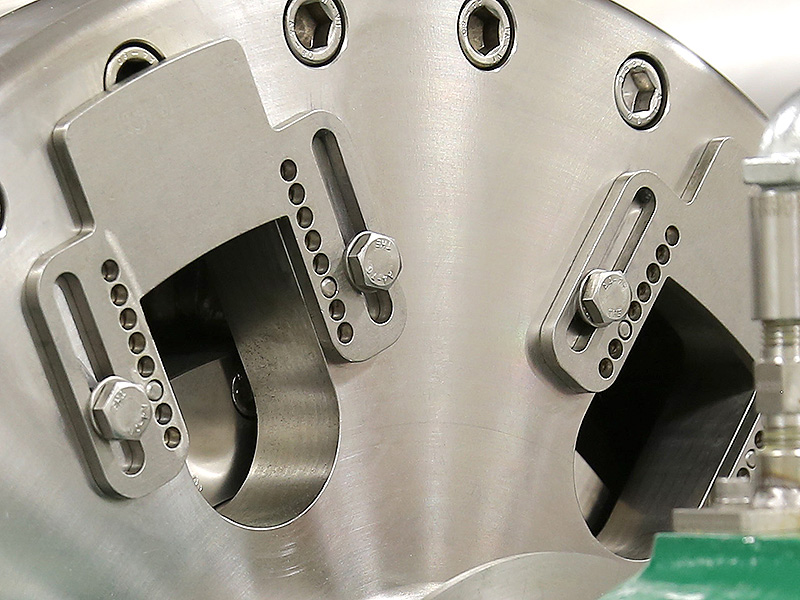

The DE-7200 VFD (Variable Frequency Drive) centrifuge offers a robust mechanical design coupled with advanced control technology, enabling it to provide consistent and effective solids control in a wide range of drilling fluid types and drilling conditions. The stainless steel bowl and conveyor with hardened and replaceable wear parts reduce the total ownership cost and maintenance downtime. Automatic load sensing and feed pump control dynamically adjusts the pump rate to maintain bowl or conveyor torque set point, enabling automated processing optimization and preventing rotating assembly overload. The DE-7200 is available with remote monitor and control capability, allowing the operator to be located outside of hazardous working environments and enabling offsite technicians to perform process optimization, quality control, and troubleshooting.

FEATURES & BENEFITS

- Allows independent adjustment of bowl speed, conveyor differential speed, and feed rate at the control cabinet

- Enables on-the-fly control of centrifuge parameters for optimal solids removal efficiency in a wide variety of applications

- Provides automated process optimization

- Dynamically adjusts feed rate based on bowl and conveyor torque

- Ensures maximum processing rate as conditions change

- Prevents rotating assembly overload and associated downtime

- Safe, consistent, and reliable performance for unattended operation

- Controls all motor acceleration during start up and shut down to ensure safe operation, protecting equipment and personnel

- Includes automatic clean out during shutdown to remove process material from the rotating assembly, extending life and reducing maintenance requirements

- Issues detailed alarm and fault messages to facilitate troubleshooting, reducing maintenance time and cost

- Monitors and logs main bearing temperatures, feed rates, and motor torques to aid in preventative maintenance and extend machine life

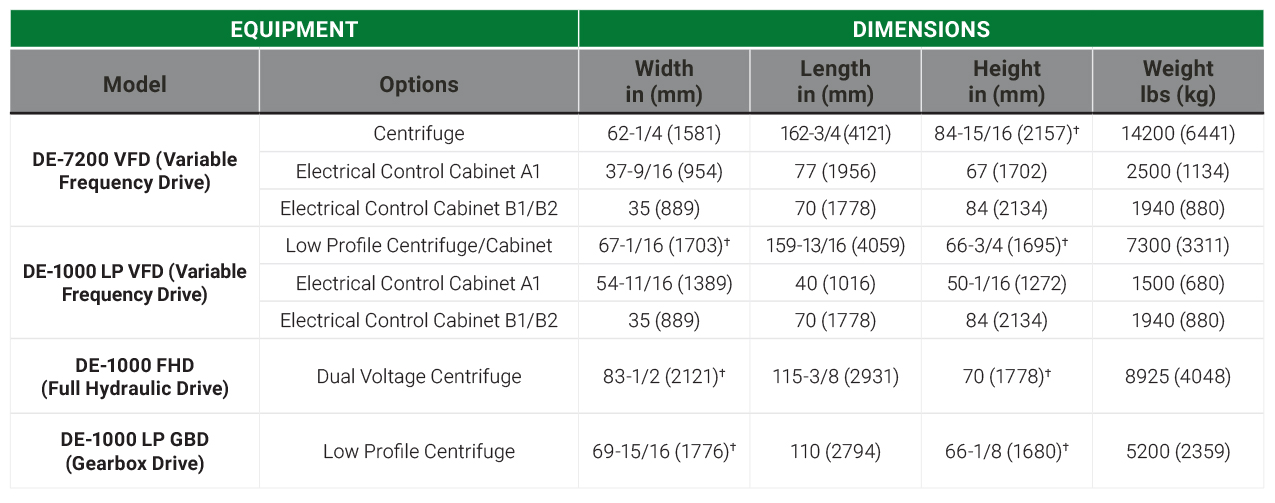

† Centrifuge Bowl Cover Open

RELATED DOCUMENTS

DE-Series Centrifuges

Fill out the form below to Download Brochure:

Field Report 151 – DE-7200 VFD Centrifuge achieves exceptional solids removal with a single pass in mud reconditioning application

Fill out the form below to Download Field Report:

Field Report 155 – DE-7200 VFD Centrifuge processes exceptional flow rate while maintaining optimal solids removal performance

Fill out the form below to Download Field Report:

Case Study 224 – Pond management equipment improves fines recovery, reduces cost at aggregate plant

Fill out the form below to Download Case Study: