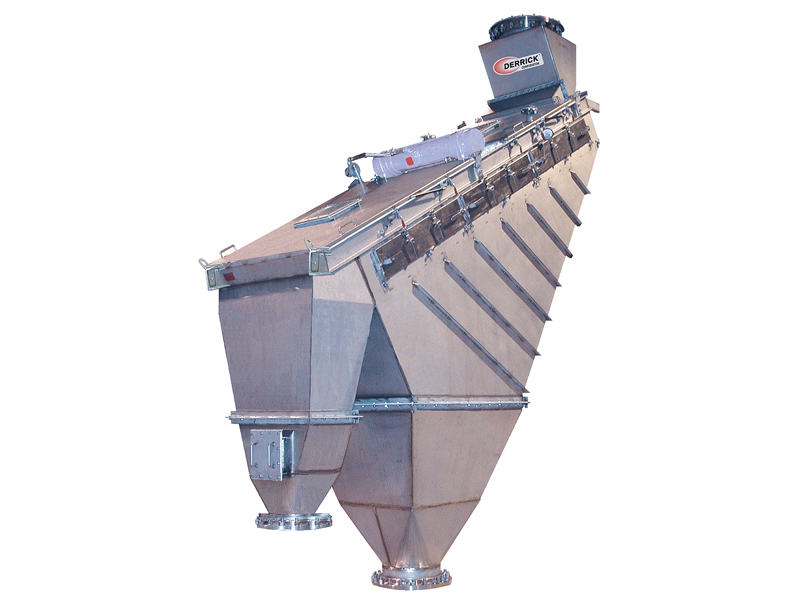

TRADITIONAL DRY SCREENING MACHINE

Derrick® Dry Sizing machines have been providing the industrial minerals industry solutions for fine dry screening application for over 60 years. Traditional Derrick dry sizing machines have utilized high speed, low amplitude, vertical elliptical motion to solve countless difficult mineral sizing challenges. Derrick’s commitment to pioneering technology has resulted in the recent evolution of dry screening technology to include dry sizing machines designed to utilize true linear motion to achieve higher capacity with small floor footprints, to include dry sizing machines that utilize an alternate parallel-to-flow screen panel tensioning system (“Front-to-Back” tensioning) to achieve higher capacity within the traditional Derrick machine footprint and to include a new series of Derrick Polyweb® urethane screen panels to provide long life, anti-blinding surfaces. Numerous machines can be found worldwide screening silica sand, iron powder, nickel powder, crushed glass, coal, polyethylene pellets/resins and many other materials.

- Health, Safety & Environment (HSE)

- Multiple Machine Sizes & Configurations

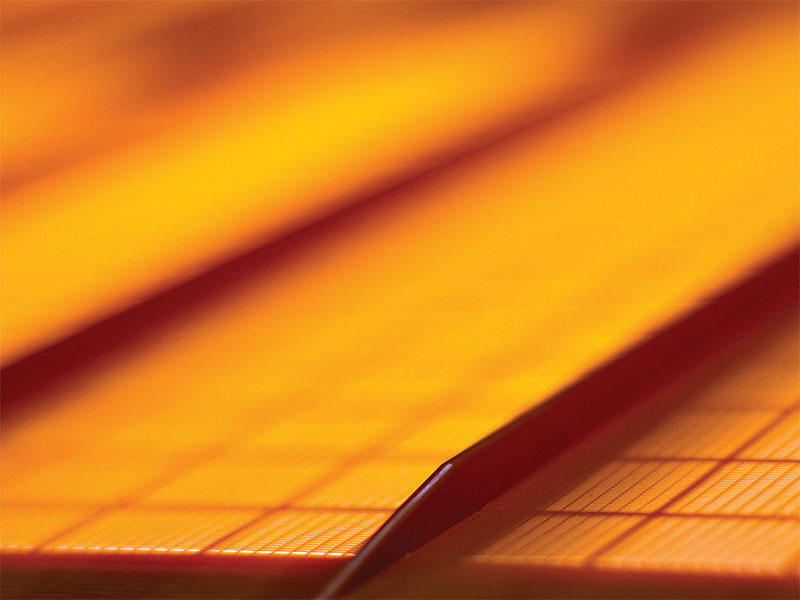

- Traditional Convex Screen Frame

- “Front-to-Back” Screen Frame

- Multi-Deck Dry Sizing Machines

- Derrick Integrated Vibratory Motors

FEATURES & BENEFITS

- Low sound production

- Full enclosures with hinged and clamped top covers and side access doors for dust suppression

- Easy screen inspection, removal and installation

- Light-weight screen panels for easy installation

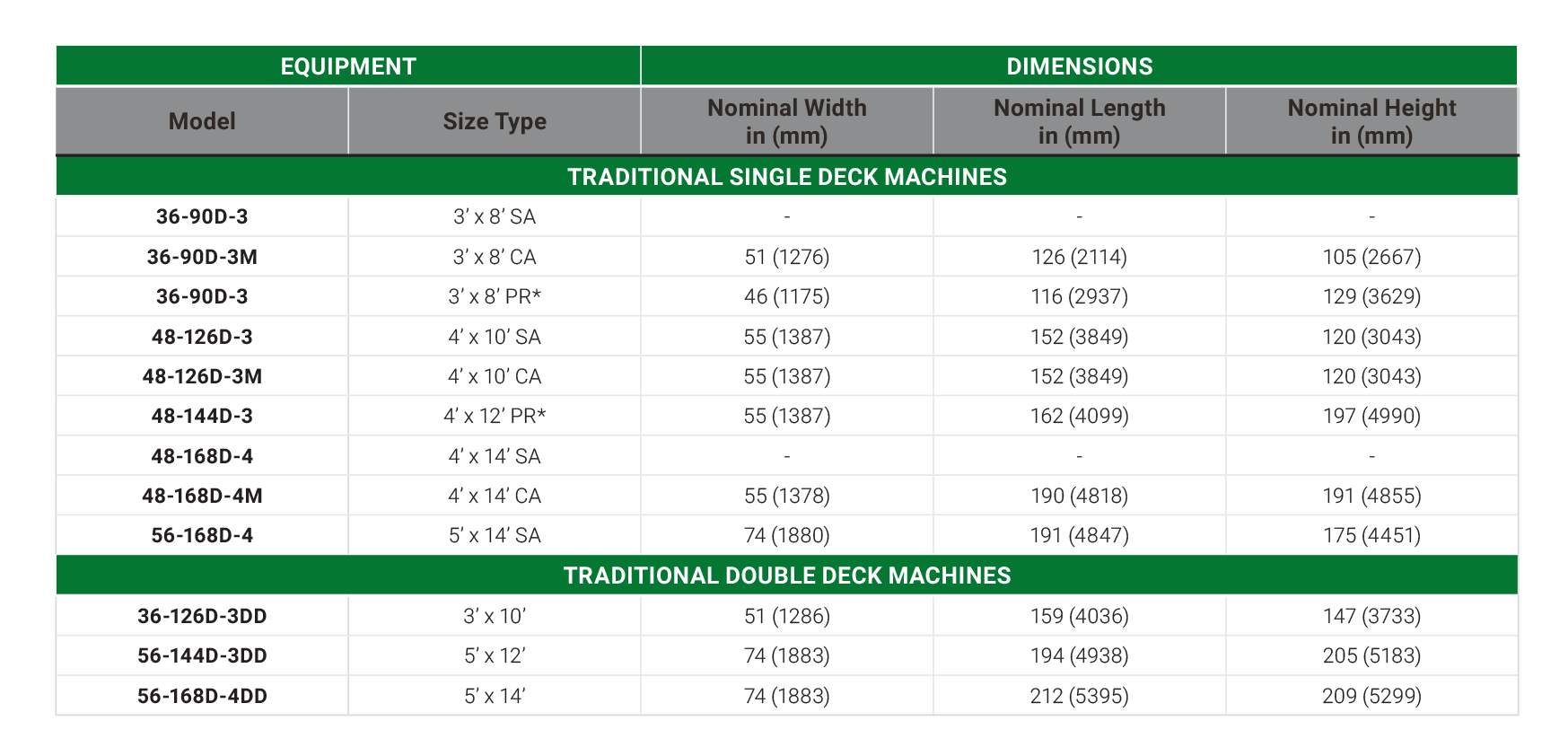

- Traditional Single-Deck available in 3 ft x 8 ft (0.9 x 2.4 m), 4 ft x 10 ft (1.2 x 3.0 m), 4 ft x 12 ft (1.2 x 3.6 m), and 5 ft x 14 ft (1.5 x 4.3 m) sizes

- Traditional Double-Deck available in 3 ft x 10 ft (0.9 x 3.0 m), 5 ft x 12 ft (1.5 x 3.6 m), and 5 ft x 14 ft (1.5 x 4.3 m) sizes

- “Front-To-Back” Single-Deck and Double-Deck are available in 4 ft x 10 ft (1.2 x 3.0 m) size

- Multi-Deck machines are available with up to four 4 ft x 10 ft (1.2 x 3.0 m) decks

- Single, double and triple undersize discharge hoppers available

- Multiple feed box styles available

- Provides dry screening capability for a wide range of mass and volumetric feed capacities

- Allows use of both Derrick Polyweb urethane and traditional wire screen panels

- Fast, easy screen panel installation and tensioning with sealing, rapid change bolt assemblies

- Unique non-blinding design for optimum efficiency and performance

- Convex screen panel sections oriented parallel to material flow

- Extremely fast, easy screen panel installation and tensioning with single tensioning point for each screen panel

- Results in high capacity as a result of full-width dispersion of solids over entire length of vibrating screen frame

- Can be fitted with various Derrick vibratory motors

- Latest Derrick dry screening machine technology

- Incorporates dual motor, true-linear motion that allows stacking of multiple single-deck machines

- Designed for exclusive use of Derrick Polyweb urethane screen panels

- Results in high capacity screening with a small floor footprint

- Zero maintenance

- Multiple options available – E3, Super G®, or W vibratory motors

- Powerful, quiet and low energy consumption

- Super G has greased-for-life bearings (Two-year Warranty)

RELATED DOCUMENTS

Dry Screening

Fill out the form below to Download Brochure:

Particle Screener

Fill out the form below to Download Brochure:

Case Study 201 – Dry chrome foundry sand production in South Africa

Fill out the form below to Download Case Study:

Case Study 216 – Two-stage dry screening process produces 97.7% overall screening efficiency

Fill out the form below to Download Case Study: