REPULP SCREEN

The Derrick® Repulp Wet Sizing Screen is the solution for difficult to screen materials that require the Oversize product fraction to meet tight quality specifications. The Repulp machine’s high speed, low amplitude motion coupled with its countercurrent spray wash water system effectively removes fine particles. It has a long history of producing high value products for numerous industrial mineral and precious metal industries. Numerous machines can be found worldwide screening silica sand, feldspar, coal, iron ore, gold ore and many other materials.

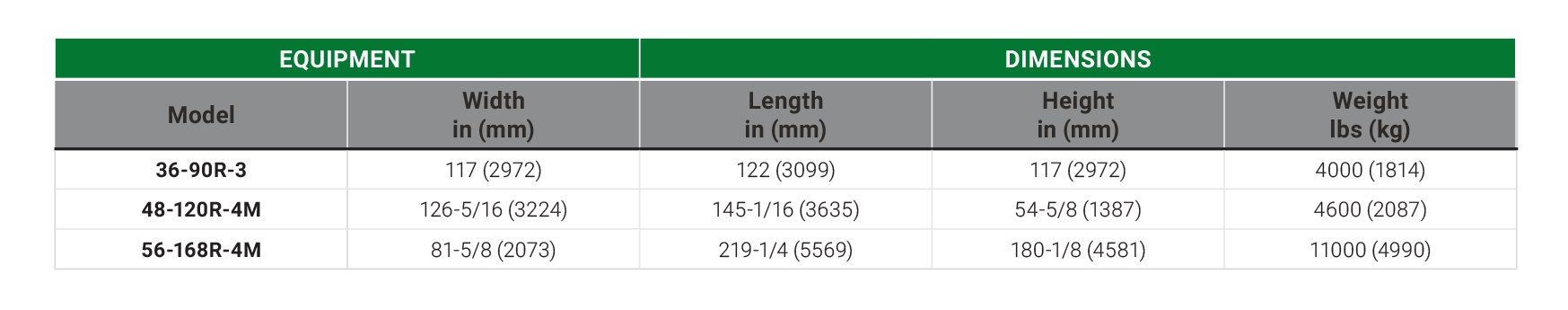

Three sizes of Repulp Wet Sizing Screens are available to meet the variable screening capacity needs of the both the industrial mineral and precious metal industries. Abrasion resistant urethane coatings and sealed-for-life Derrick vibrators assure long-life, low maintenance operation. The machines’ versatile design allows for the use of both traditional wire and Derrick anti-blinding, high open area Polyweb® urethane screen panels. The combination of these features ensure outstanding wet screening performance with minimal operator involvement.

FEATURES & BENEFITS

- Low sound production

- Easy screen inspection, removal and installation

- Light-weight screen panels for easy installation

- Available in 3 ft x 8 ft (0.9 x 2.4 m), 4 ft x 10 ft (1.2 x 3.0 m) and 5 ft x 14 ft (1.5 x 4.3 m) sizes

- Single, double and triple undersize discharge hoppers available

- Multiple feed box styles available

- Provides wet screening capability for a wide range of mass and volumetric feed capacities

- Open design allows visual inspection of screen panels

- Rubber lined troughs between each screen panel

- Wash water spray bars with multiple nozzle styles

- Enhances removal of fines from oversize fraction

- Allows use of both Derrick Polyweb urethane and traditional wire screen panels as fine as 325 mesh (45 microns)

- Fast, easy screen panel installation and tensioning with sealing, rapid change bolt assemblies

- Zero maintenance

- Three options available – E3, Super G®, or W vibratory motors

- Powerful, quiet and low energy consumption

- Super G has greased-for-life bearings (Two year warranty)

- Linear motion mount available for use with Super G vibratory motors

- Zinc Rich Enamel Primer with Enamel Top Coat exterior/interior coating for low abrasion applications

- 100% solids urethane coating for vibrating screen frame for high abrasion applications

- Bonded rubber, nitrile rubber and 100% solids urethane linings for feed boxes and discharge hoppers for high abrasion applications.

RELATED DOCUMENTS

Repulp Wet Sizing Screen

Fill out the form below to Download Brochure:

Case Study 217 – Indian mineral sands producer improves grade and recovery of garnet

Fill out the form below to Download Case Study:

Case Study 232 – Derrick® Repulp Screen improves gravity circuit feed and eliminates foundation vibrational damage

Fill out the form below to Download Case Study:

Case Study 241 – Improved Heavy Media Screening Efficiency Results in Rapid Return on Investment – Less than One Month!

Fill out the form below to Download Case Study: