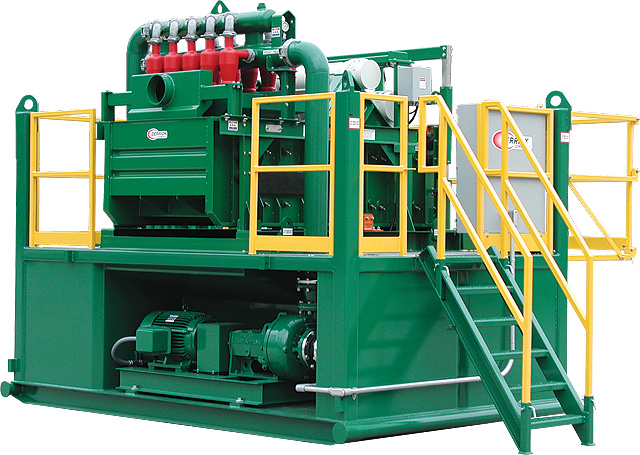

MINI SEPARATION SYSTEM

The Mini Separation System offers ultra-fine separation in a very small footprint. Coarse mesh scalping is achieved by the lower deck of the Derrick FLC™ 423™ linear motion shaker, which is outfitted with long life, high open area, fine Polyweb® urethane screen panels. Screen underflow is then processed through ten 4’’ Derrick desilting cones. Cone underflow is routed onto the top deck which is typically outfitted with fine Pyramid® screens with openings in the API 140 to 200 range. Cleaned fluid is then returned to the excavation.

- Derrick FLC 423 Double Deck Screening Machine

- Desilter Feed Pump

- Control Panel

- 12′ Skid Mounted Tank

FEATURES & BENEFITS

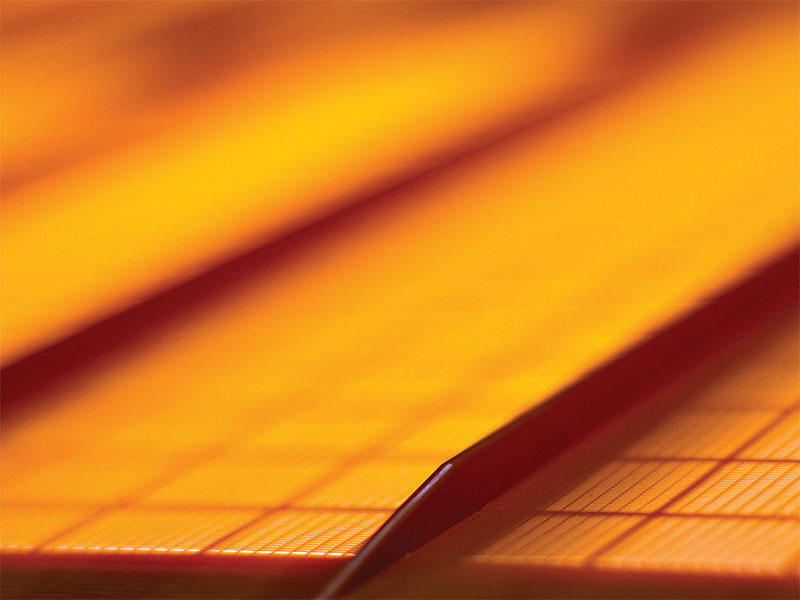

- Scalping on lower deck using high open area, long life Urethane screens (2.0 to 0.15 mm/10 to 100 mesh)

- 10-Way 4” Derrick desilting cones (.0025 mm separation)

- Desilting underflow across upper deck equipped with Pyramid® screens (0.106 to 0.053/140 to 270 mesh)

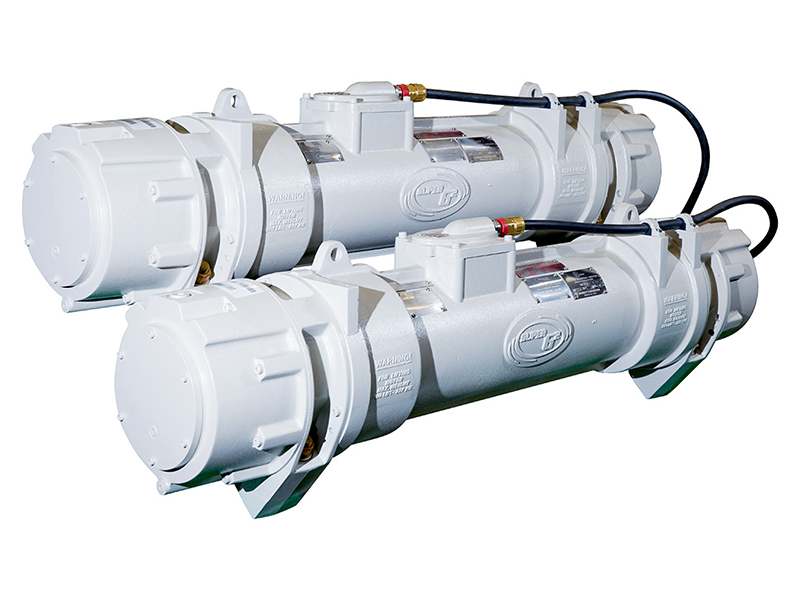

- Super G® vibratory motors provide continuous high G-force linear motion

- 6 x 5 x 11 with mechanical seal

- 440/480 volt, 3 phase, 60 Hz (110 single phase accessory plug available)

- Walkway, grating, handrail and stairs assure safe operation

RELATED DOCUMENTS

Solids Control for Civil Construction

Fill out the form below to Download Brochure:

Case Study 300 – Derrick® Mini Separation System and DE-7200™ VFD™ optimize cutter soil mixing technology project

Fill out the form below to Download Case Study: