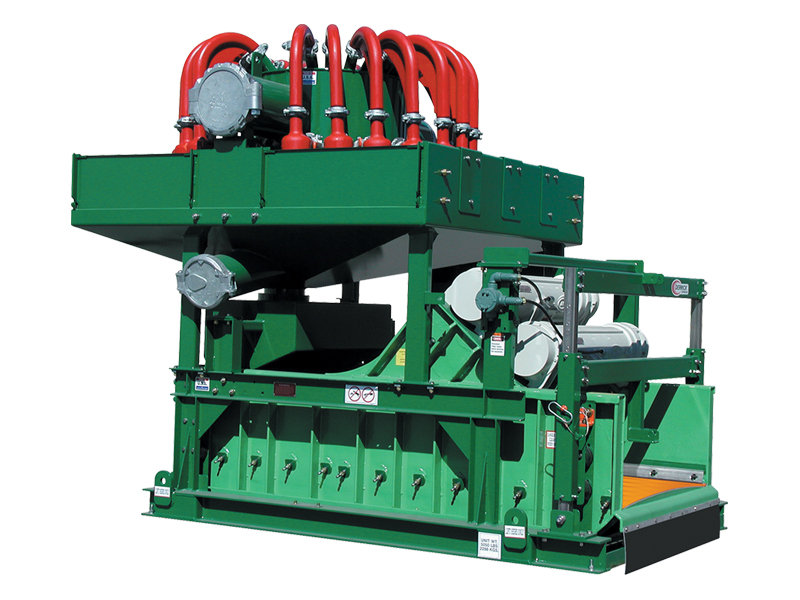

HI-G® DEWATERING MACHINE

The Derrick HI-G® Dewatering Machine provides the most cost-effective solution to handling fine solids separation. Derrick’s HI-G Dewatering Machine consists of a cluster of 4″ hydrocyclones mounted over a high G performance linear motion screening unit.

- Hydrocyclones

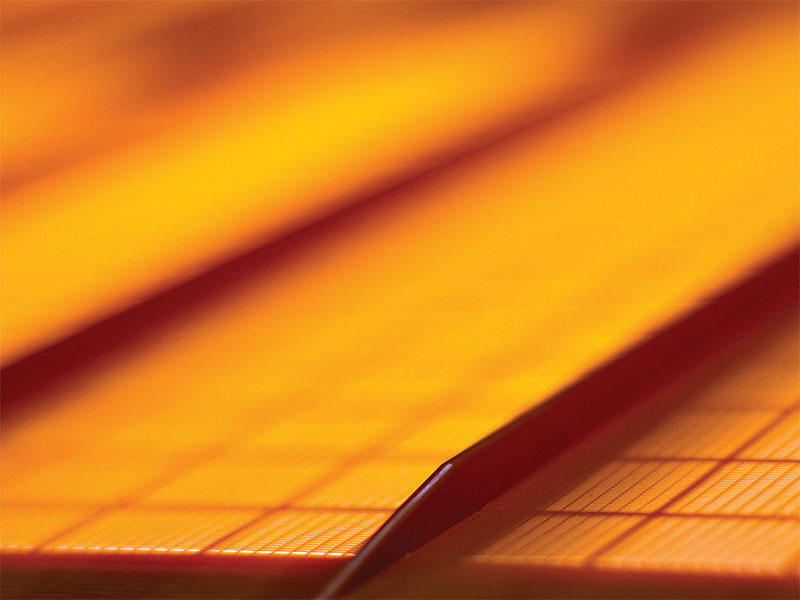

- Polyweb® Urethane Screens

- Super G® Integrated Vibratory Motors

FEATURES & BENEFITS

- Available in 10, 12, 16, and 20 cone models

- Uniform pressure balance operation through round design

- Shut-off valves on each cone inlet

- Vacuum breaker connection

- Low cost polyurethane and ceramic cone inserts engineered to minimize wear and maintenance

- Accessible pressurized section of manifold to allow for liner maintenance

- Superior capacity and performance with high open area of 35 to 45 percent

- Reduced operating and maintenance costs from long life and ease of installation

- Available with openings as fine as 325 mesh (45 μm)

- Practically non-blinding

- Can be repaired or patched in place

- Custom mold designs

- Zero maintenance

- Powerful, quiet, dual vibratory motors provide continuous high G-force linear motion

- Super G has greased-for-life bearings (Two-year warranty)

RELATED DOCUMENTS

HI-G Dewatering Machine

Fill out the form below to Download Brochure:

Case Study 206 – Derrick Dewatering Technology Increases Product Quality for Aggregate Producers

Fill out the form below to Download Case Study:

Case Study 215 – Derrick sand production and fines recovery systems provide high quality sand products and reduce need for vast settling ponds

Fill out the form below to Download Case Study:

Case Study 224 – Pond management equipment improves fines recovery, reduces cost at aggregate plant

Fill out the form below to Download Case Study:

Case Study 242 – Screen Eliminates Tailing Pond at Chrome Producer in South Africa

Fill out the form below to Download Case Study: