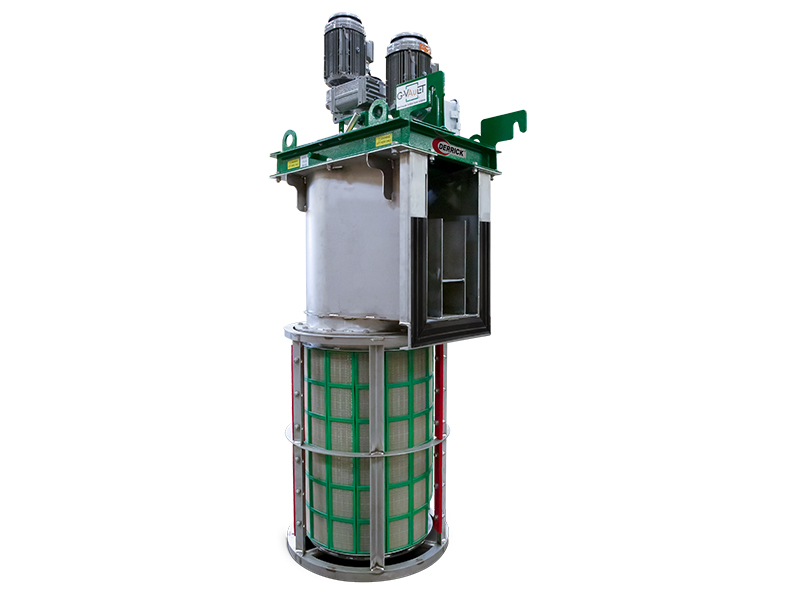

G-Vault® Complete Interstage Unit

The G-Vault® Complete Interstage Unit is the newest addition to the Derrick portfolio and now serves as the new standard of interstage screening in loaded Carbon and Resin circuits, unique to gold recovery.

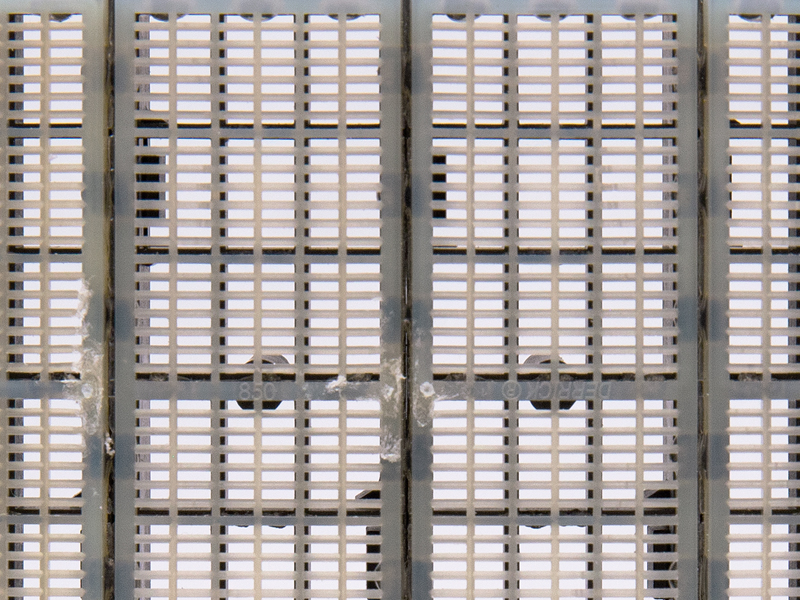

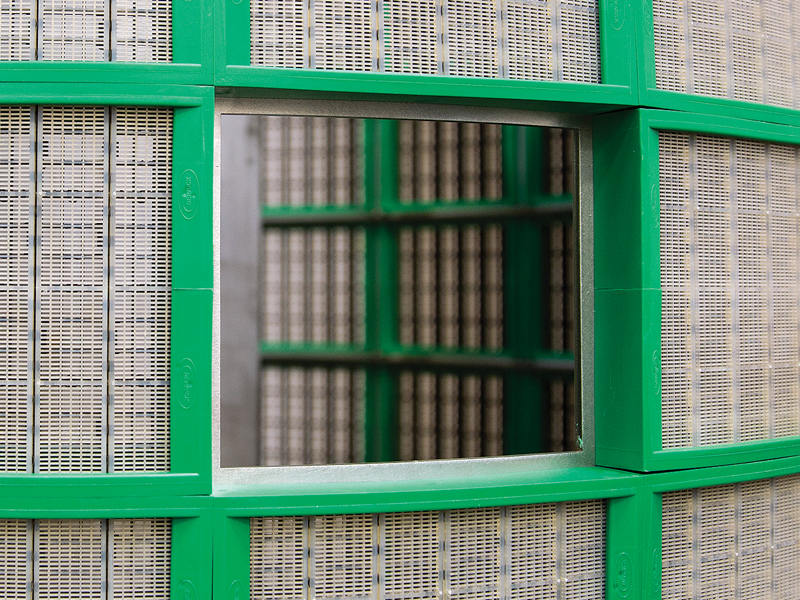

Our newest innovation employs a modular approach where a screen surface is combined with a robust support structure that can be connected with ease. Trilogy screens feature tapered openings, can withstand higher temperatures, and increased open area which all contribute to its non-blinding characteristics. These non-blinding and abrasion resistant properties result in a screen with higher throughput, increased life, and less maintenance. All of which lead to more efficient recovery.

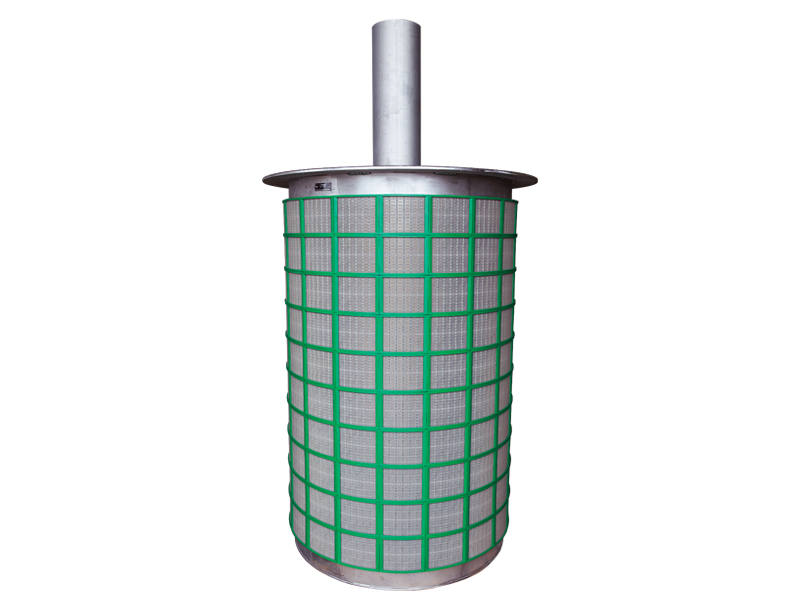

Prioritizing HSE, Derrick has focused the G-Vault design on operator safety. The G-Vault utilizes a compression seal drain on the bottom of the unit, eliminating unnecessary moving parts. An optional draft tube can be incorporated for pumping applications. This option operates on a standalone drive system which is accessible from the top of unit. Additionally, each screen on the G-Vault unit can be easily removed while connected to the launder due to its modular design – all of which lead to a reduction in working under suspended loads.

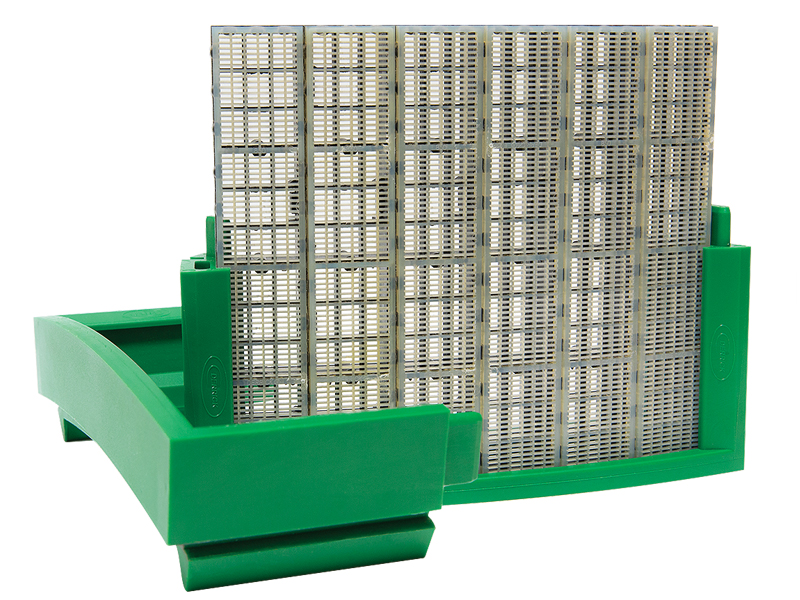

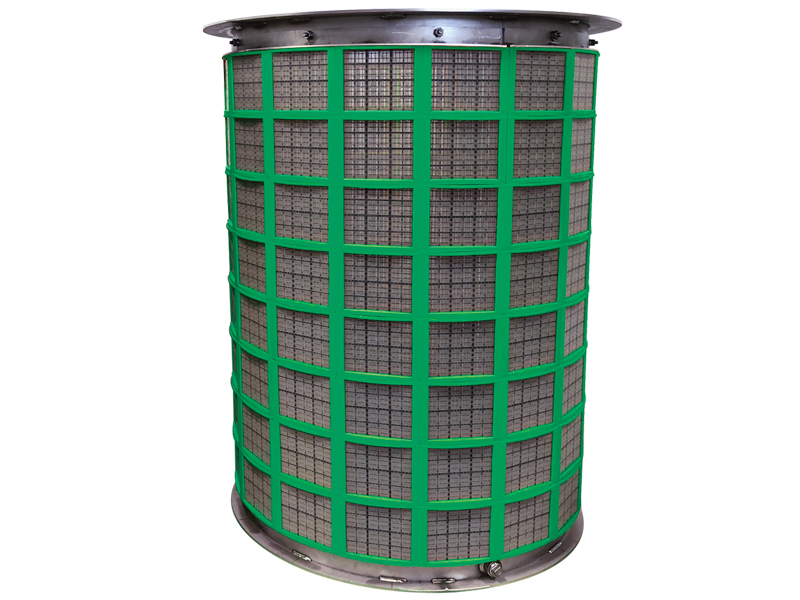

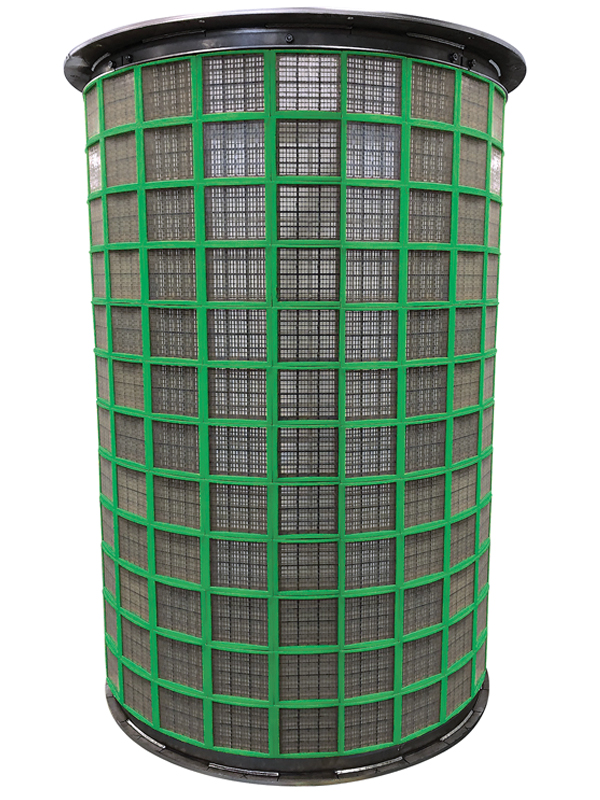

G-VAULT URETHANE INTERSTAGE SCREEN REPLACEMENT

The New Standard of Operation for CIL/CIP and RIL/RIP

The Derrick G-Vault® Urethane Interstage Screen is a direct bolt-in interstage screen replacement that utilizes Derrick’s patented urethane screen surface technology and serves as a welcome alternative to traditional stainless-steel wedge wire screens. The combination of our urethane’s abrasion resistant properties and non-blinding technology results in screen systems with significantly higher throughput, increased life, less maintenance and less tank bypass. The G-Vault screens employ a modular approach where the screen surface is combined with a robust support structure. Each screen on the G-Vault can be easily removed while connected to the launder due to this modular design. Multiple basket sizes are available with screens ranging from 500 to 1200 micron apertures.

DERRICK EXCLUSIVE TECHNOLOGY

- Increased capacities

- Accurate cut points

- Decrease in carbon losses

- Decrease in tank bypass

- Decrease in maintenance of interstage units

- Reduction of waste to tails

- More consistent CIL/CIP operations

- HSE Improvements

RELATED DOCUMENTS

G-Vault Complete Interstage Unit

Fill out the form below to Download Brochure:

G-Vault Urethane Interstage Screen

Fill out the form below to Download Brochure:

Case Study 236 – Derrick® G-Vault™ Interstage Screen offers Dramatic Payback

Fill out the form below to Download Case Study:

Case Study 237 – Derrick G-Vault® increases production and lowers maintenance costs at Ontario Gold producer.

Fill out the form below to Download Case Study:

Case Study 238 – Derrick® G-Vault® technology outperforms wedge wire screens at Oceana Gold’s Haile Gold Mine’s CIL circuit

Fill out the form below to Download Case Study:

Advancements in Interstage Screening Using Synthetic Media to Improve Performance at Nevada Gold Mines Resin In Leach Facility.

Fill out the form below to Download White Paper:

INTERSTAGE SCREENING EVOLUTION, RETROFITTING OCEANAGOLD’S HAILE GOLD MINE’S CIL INTERSTAGE SCREENS WITH URETHANE SCREENING SURFACES AND THE INCREASED SAVINGS AND PERFORMANCE.

Fill out the form below to Download White Paper:

Article – Natural Resources Review – Derrick’s Golden Plan

Fill out the form below to Download Article: