FLO-LINE CLEANER™ 500

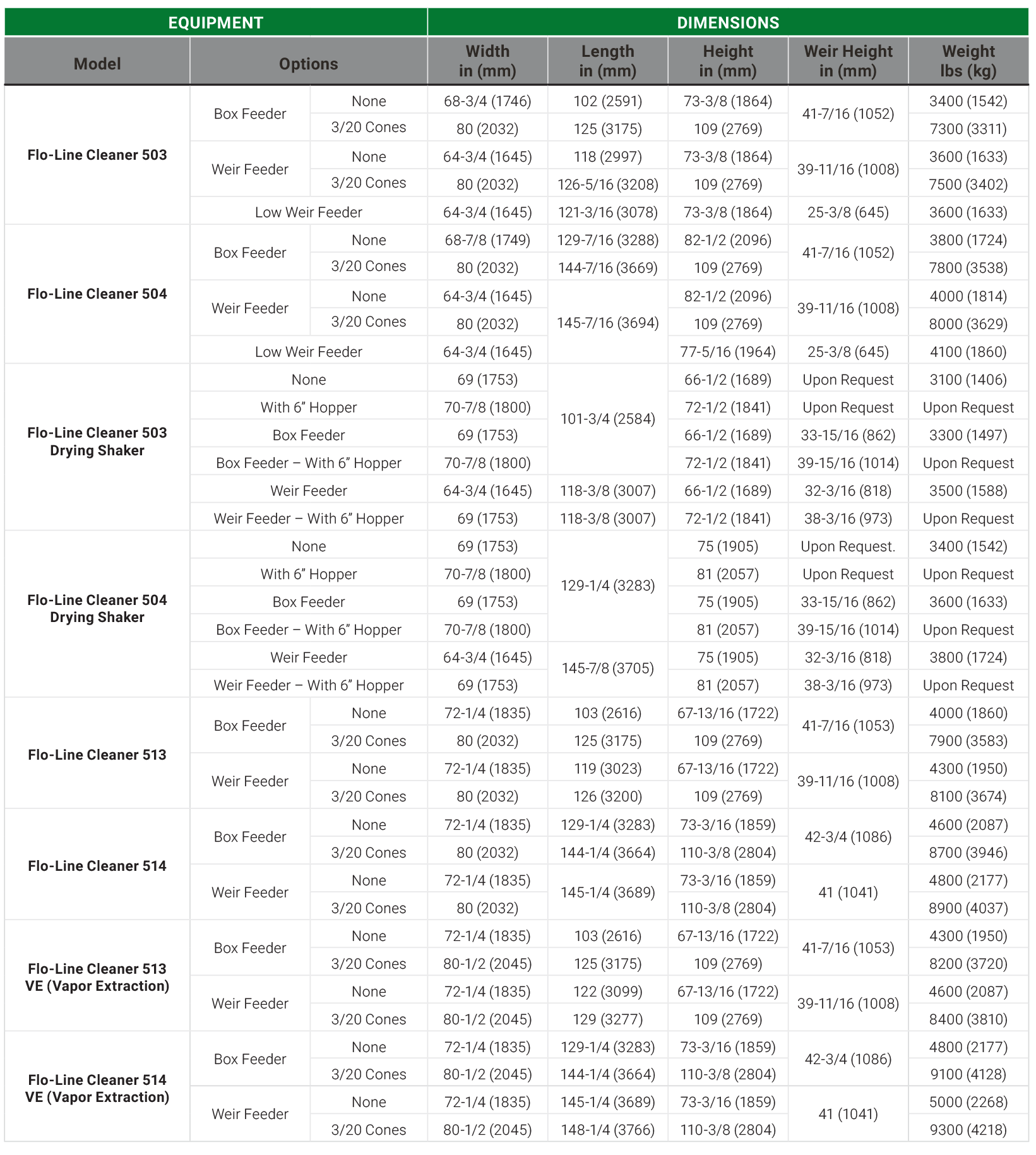

With over 15 years of offshore and onshore rig installations, Derrick’s Flo-Line Cleaner™ 500 Series shakers embody an industry-proven balance of product dependability and enhanced performance. Designed with the customer in mind, the Flo-Line Cleaner offers user-friendly technology such as light-weight screens, adjustable screen angle while drilling, and single-side screen tensioning.

The Flo-Line Cleaner’s modular design allows for versatile configuration as a durable flow line shaker, high performance mud cleaner, single skid dual unit, or even as a drying shaker.

- Health Safety & Environment (HSE)

- Convex Screen Bed & Quik-Lok Tension System

- Pyramid® Screen Technology

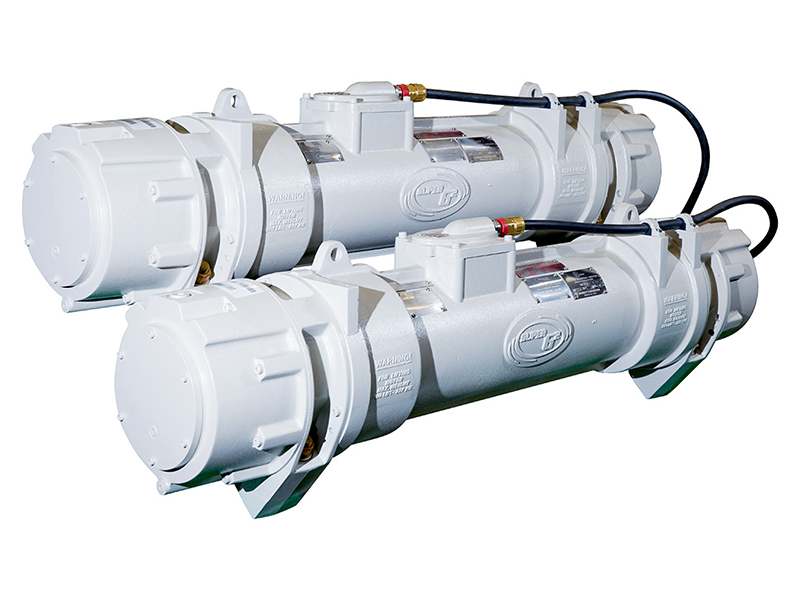

- Super G2® & Super G® Integrated Vibratory Motors

- Single Point Screen Angle Adjustment

- Mud Cleaner

FEATURES & BENEFITS

- Easy screen inspection, removal, and installation

- Low sound production (74 +/- 4 dBA)

- Optional vapor extraction covers protect operating personnel and surrounding equipment from vapors

emitted during the screening process (dependent on customer provided HVAC exhaust system) - Light-weight screen panels make for easy installation

- Rugged stainless steel construction screen bed materials for long life

- Convex screen bed for increased efficiency in a smaller footprint

- Less than one minute per screen panel change

- Fast, secure panel retention

- Single-side operation, available in either left or right side

- Pyramid and Pyramid Plus screens offer up to 39% more API RP 13C non-blanked screen area over conventional shakers with a FLC 503/513 and up to 85% with a FLC 504/514, delivering greater efficiency

- Compliant with industry-standard API RP 13C (ISO 13501)

- Zero maintenance

- Powerful, quiet, dual vibratory motors apply high G performance

- Super G vibratory motors are standard for FLC 503 and 504

- Super G2 vibratory motors are standard for FLC 513 and 514

- Super G has greased-for-life bearings (Two-year warranty)

- Super G2 has continuous recirculating internal oil lubrication system (Three-year warranty)

- Adjustable screen angle while drilling from -1° to +5° (FLC 513 and 503) and -1° to +7° (FLC 514 and 504) for optimum capacity, screen life, and efficiency

- Single point system allows one man operation and optimization while drilling

- Hydraulic push-button system on FLC 513/514

- Manual ratchet system on FLC 503/504

- Up to twenty 4” hydrocyclones

- Up to three 10” hydrocyclones

- Optional individual shutoff valve for each 4″ hydrocyclone

RELATED DOCUMENTS

Solids Control for Oil and Gas Drilling

Fill out the form below to Download Brochure:

Solids Control for Civil Construction

Fill out the form below to Download Brochure: