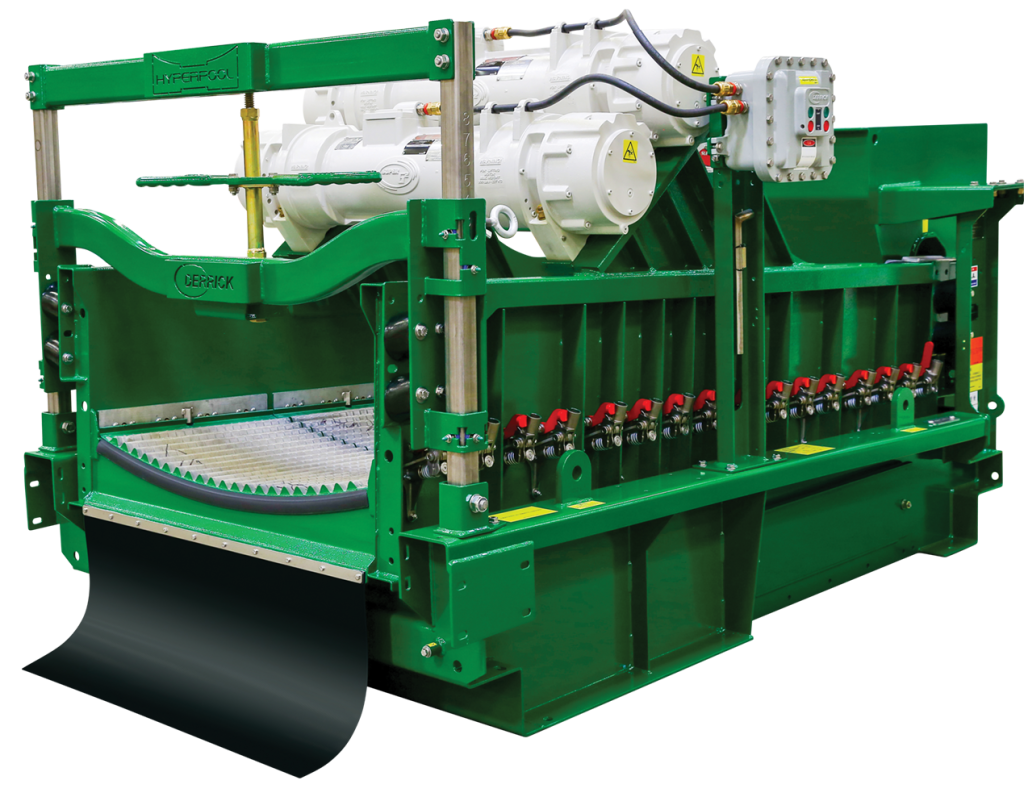

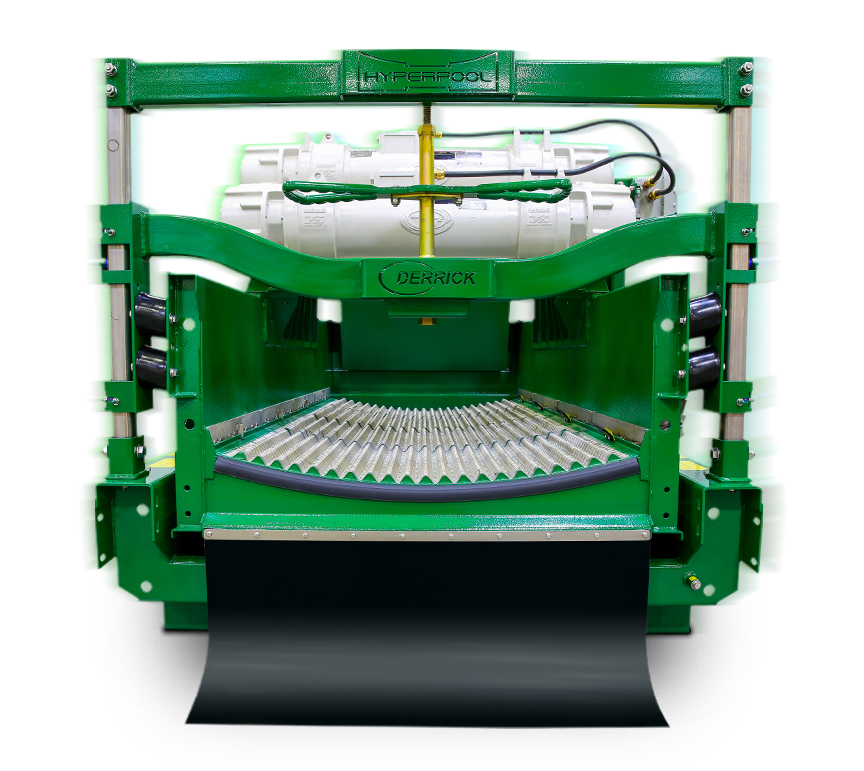

Backed by over 60 years of cost-effective solutions plus award-winning service, the Derrick Hyperpool® shaker is the latest in a long line of products designed expressly to exceed the demanding needs of today’s oilfield drilling operations.

With its compact footprint, industry-leading processing capacity, solids bypass prevention, and low maintenance cost, the Hyperpool is well suited for all drilling applications where drilling performance and rig modularity are required. The Hyperpool is designed to bring maximum value to the customer.