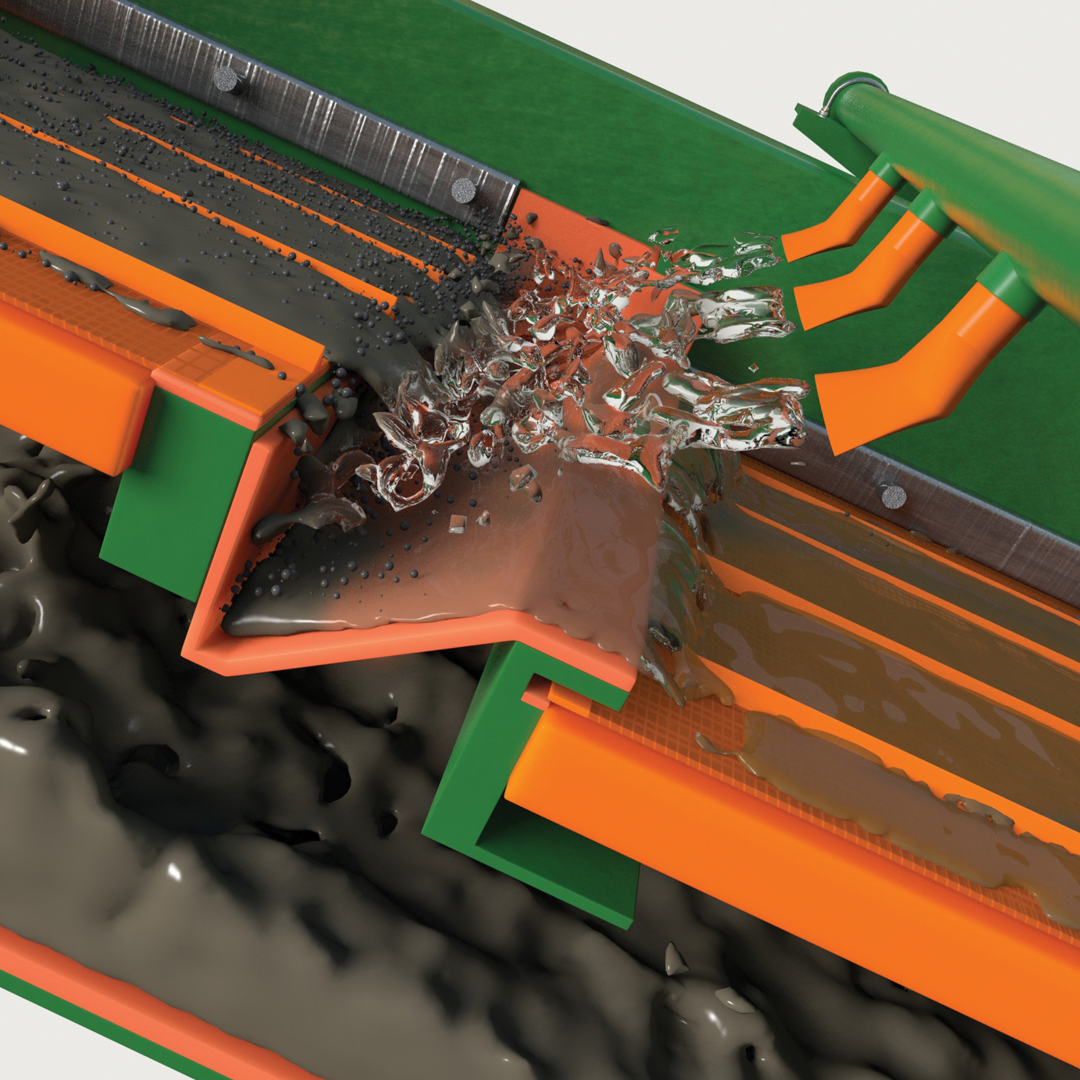

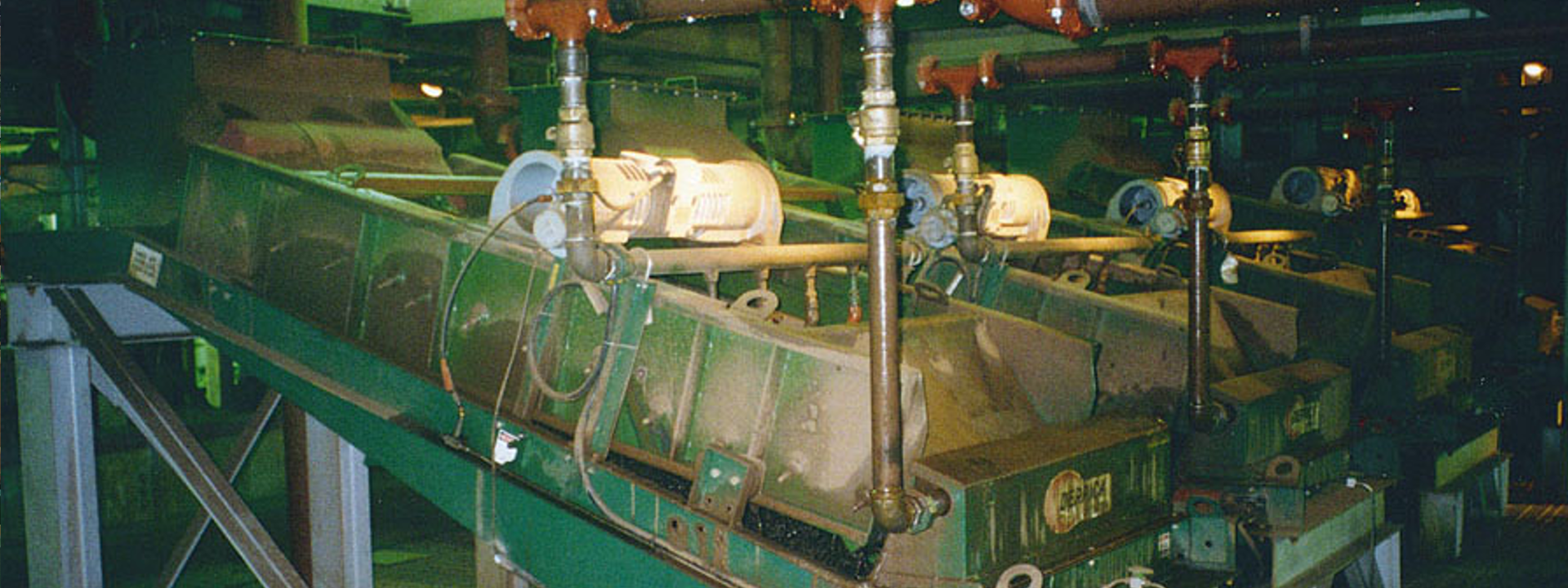

The Derrick® Repulp Wet Sizing Screen is the solution for difficult to screen materials that require the oversize product fraction to meet tight quality specifications. The Repulp machine’s high speed, low amplitude motion coupled with its countercurrent spray wash water system effectively removes fine particles. It has a long history of producing high value products for numerous industrial mineral and precious metal industries. Numerous machines can be found worldwide screening silica sand, feldspar, coal, iron ore, gold ore, and many other materials.

Three sizes of Repulp Wet Sizing Screens are available to meet the variable screening capacity needs of both the industrial mineral and precious metal industries. Abrasion resistant urethane coatings and sealed-for-life Derrick vibrators assure long-life, low maintenance operation. The machine’s versatile design allows for the use of both traditional wire and Derrick anti-blinding, high open area Polyweb® urethane screen panels. The combination of these features ensures outstanding wet screening performance with minimal operator involvement.