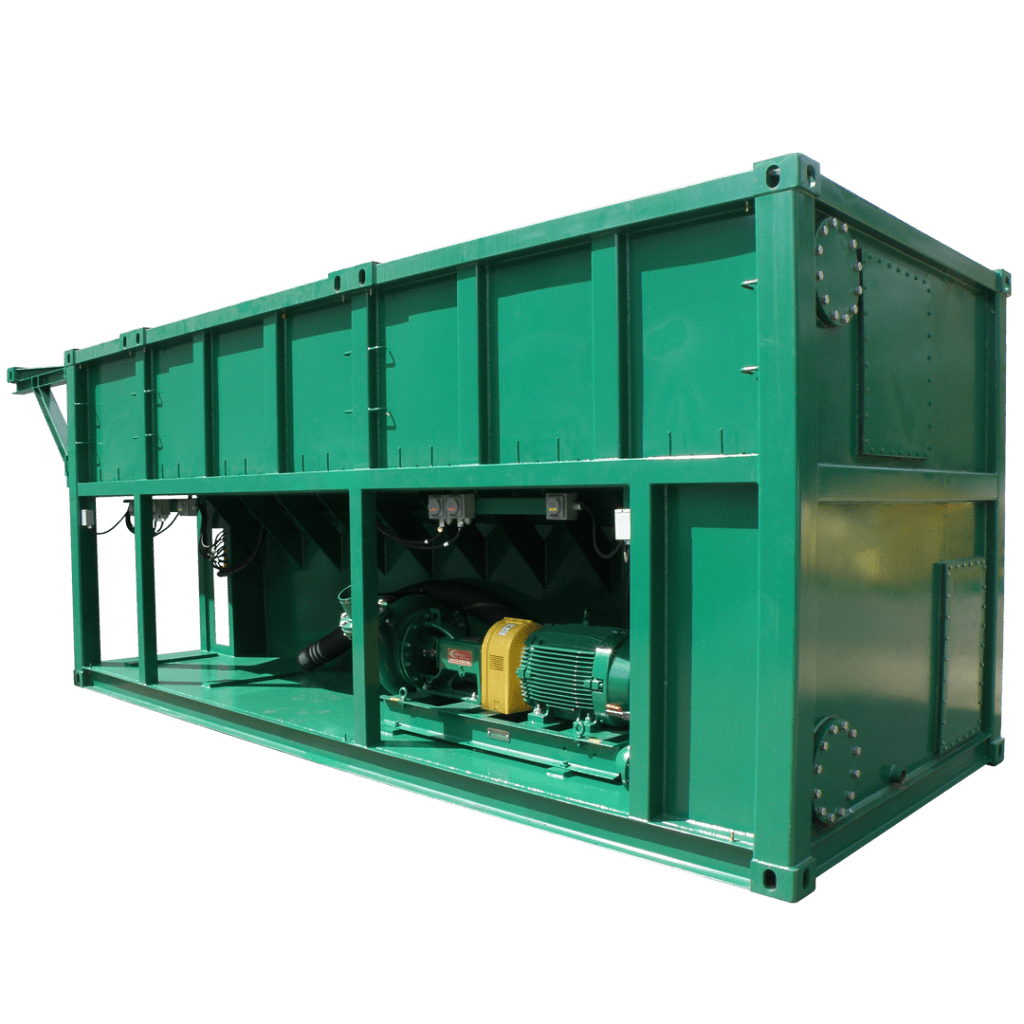

Utilizing Platform Strategy, Derrick’s versatile Modular Slurry Separation Plant can be used for various civil construction applications such as horizontal drilling, microtunneling, and slurry wall milling. The innovative design provides optimal flexibility for a wide range of ground conditions. The plant integrates a three-chambered modular base tank with electrical control panel, one or two centrifugal pumps to feed the hydrocyclones, and shaker platform(s). The base tank can accommodate up to three Derrick equipment platforms for multiple slurry separation equipment combinations to meet the end-user requirements.