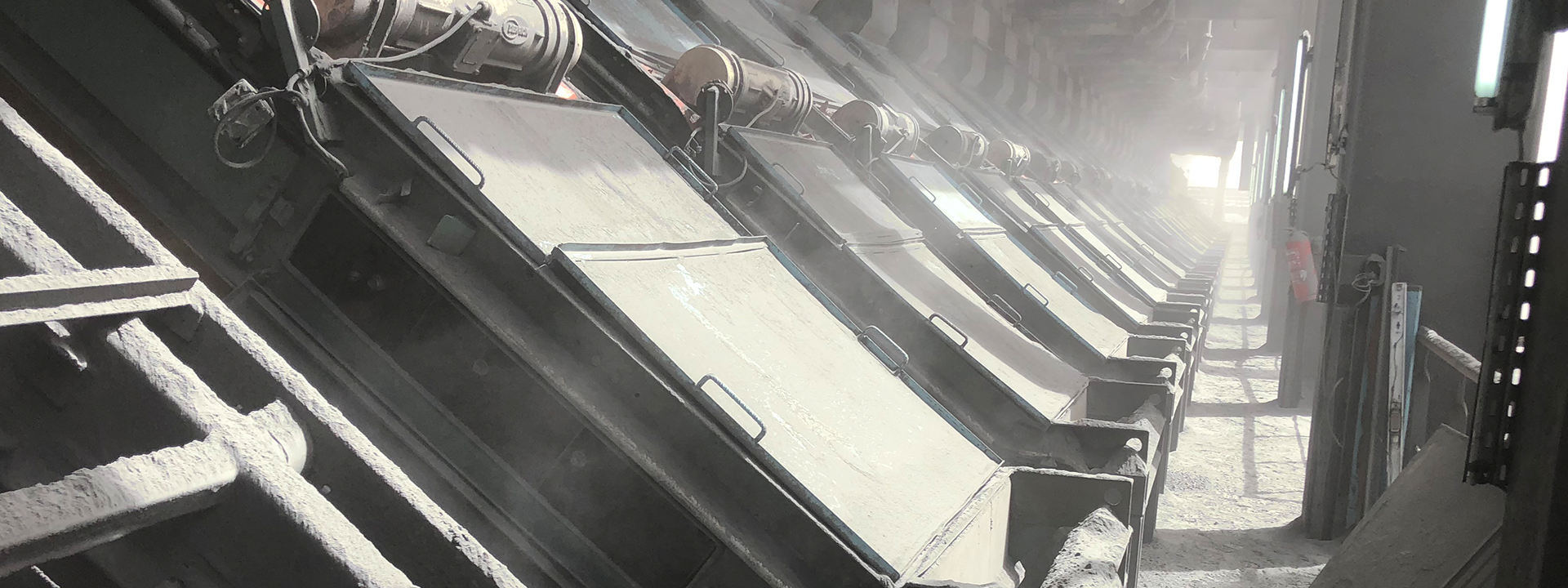

Derrick® Dry Sizing machines have been providing fine dry screening solutions to the industrial minerals industry for over 60 years. Traditional Derrick dry sizing machines utilize high speed, low amplitude, vertical elliptical motion to solve countless difficult mineral sizing challenges.

Continued development of the technology has evolved to include dry sizing machines that utilize true linear motion and an alternate parallel-to-flow screen panel tensioning system (“Front-to-Back” tensioning) to achieve higher capacity in a compact footprint.

Compatability with Derrick’s Polyweb® provide long life, anti-blinding surfaces.

Numerous machines can be found worldwide screening silica sand, iron powder, nickel powder, crushed glass, coal, polyethylene pellets/resins, and many other materials.