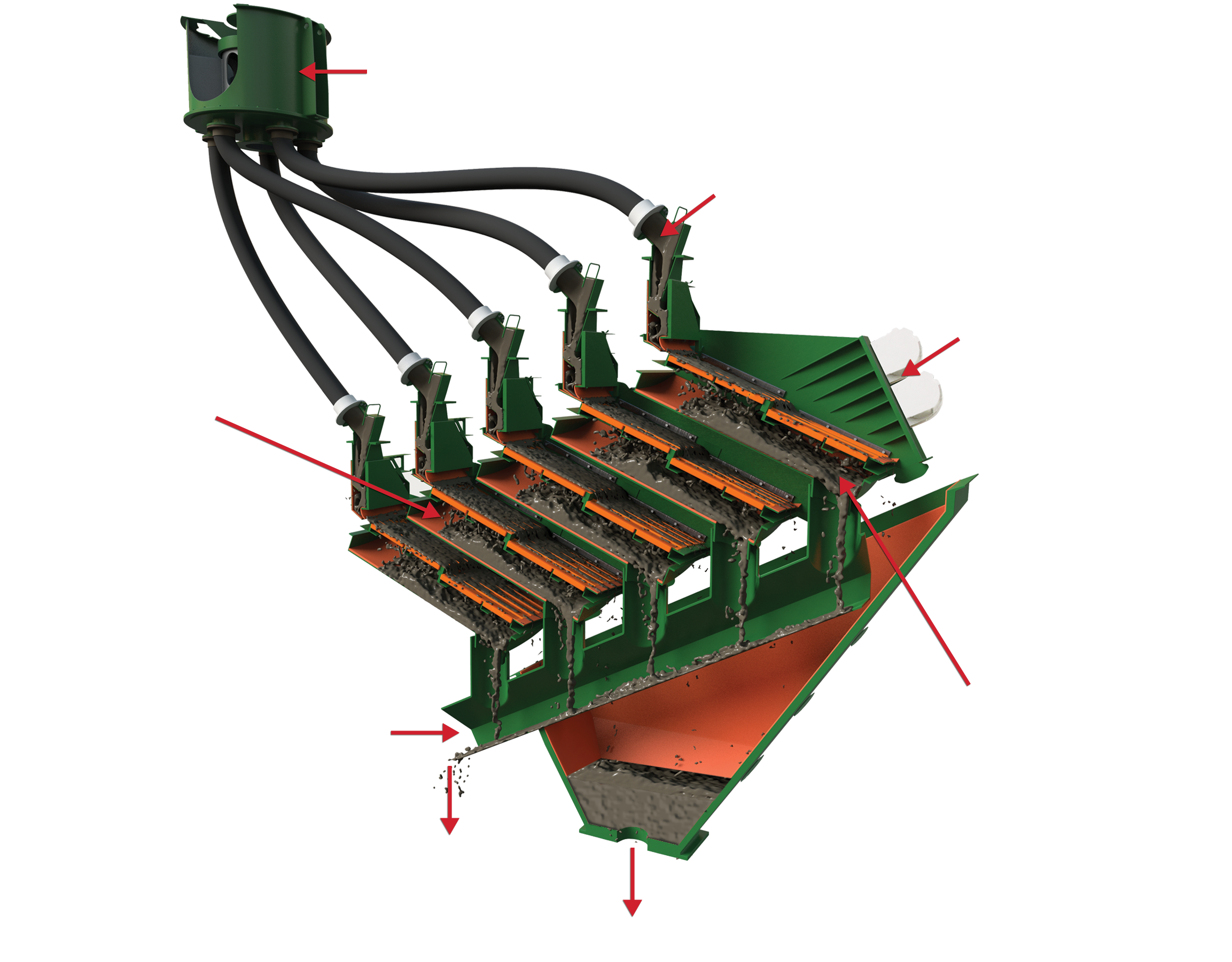

The Derrick Stack Sizer® redefines fine particle wet screening, offering high capacity and exceptional efficiency in a compact footprint. Consisting of up to five individual screen decks positioned one above the other and operating in parallel, the Stack Sizer provides a unique combination of high capacity and efficiency that sets the Stack Sizer far above the nearest competition.

Operators worldwide are using the Stack Sizer in a wide variety of applications and capitalizing on the numerous benefits of these remarkable machines to earn significant returns.