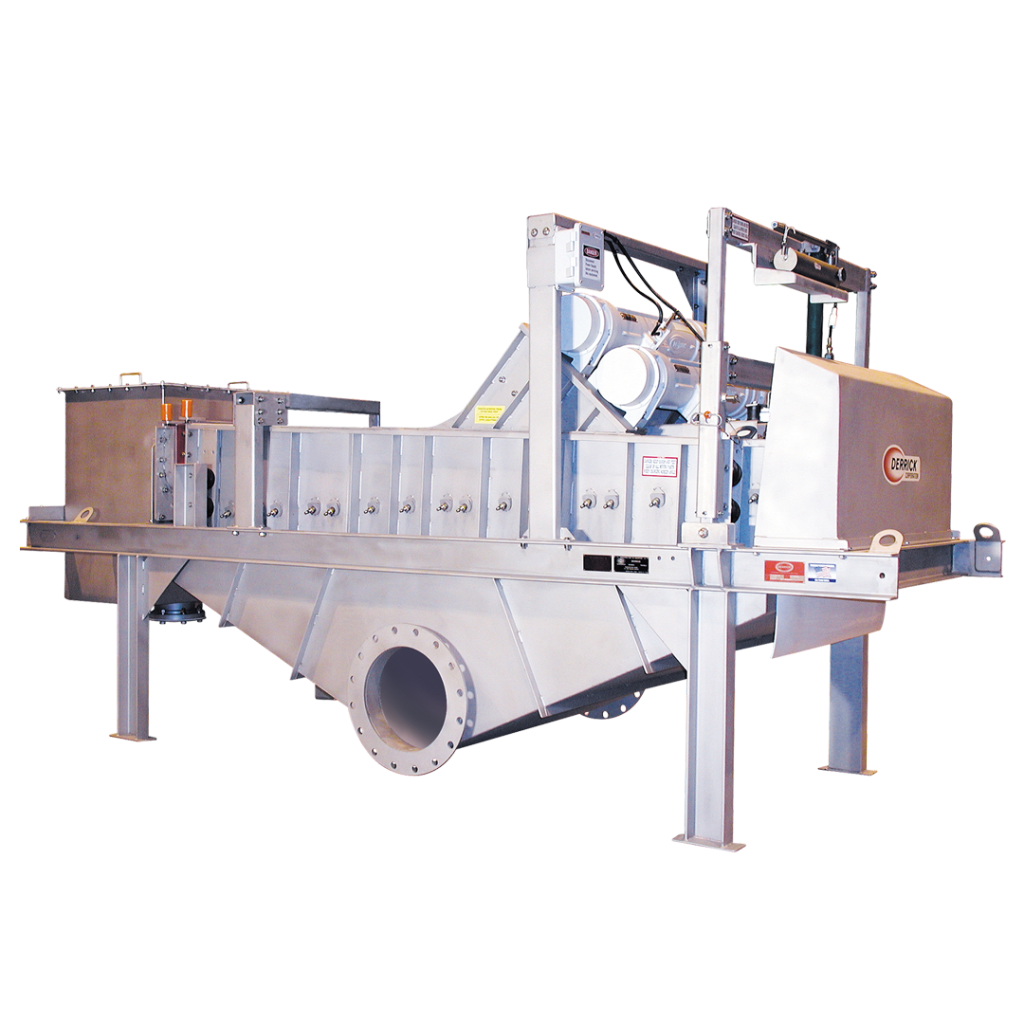

Derrick® Linear Motion Screens have a long history of performing in trash screening and wet scalping applications. They are designed for high volumetric capacity when fed dilute slurry with a low percentage of oversize solids.

Four sizes of Linear Motion Screens are available to meet the variable screening capacity needs of the industrial minerals, precious metals, industrial wastewater and municipal wastewater industries. Abrasion resistant urethane coatings and sealed-for-life Derrick vibrators assure long-life, low maintenance operation.

The equipment’s versatile design allows for the use of both traditional wire and Derrick anti-blinding, high open area Polyweb® urethane screen panels. The combination of these features ensure outstanding wet screening and dewatering performance with minimal operator involvement.

Numerous systems can be found operating in sand, aggregate, coal, concrete, graphite dewatering applications worldwide.