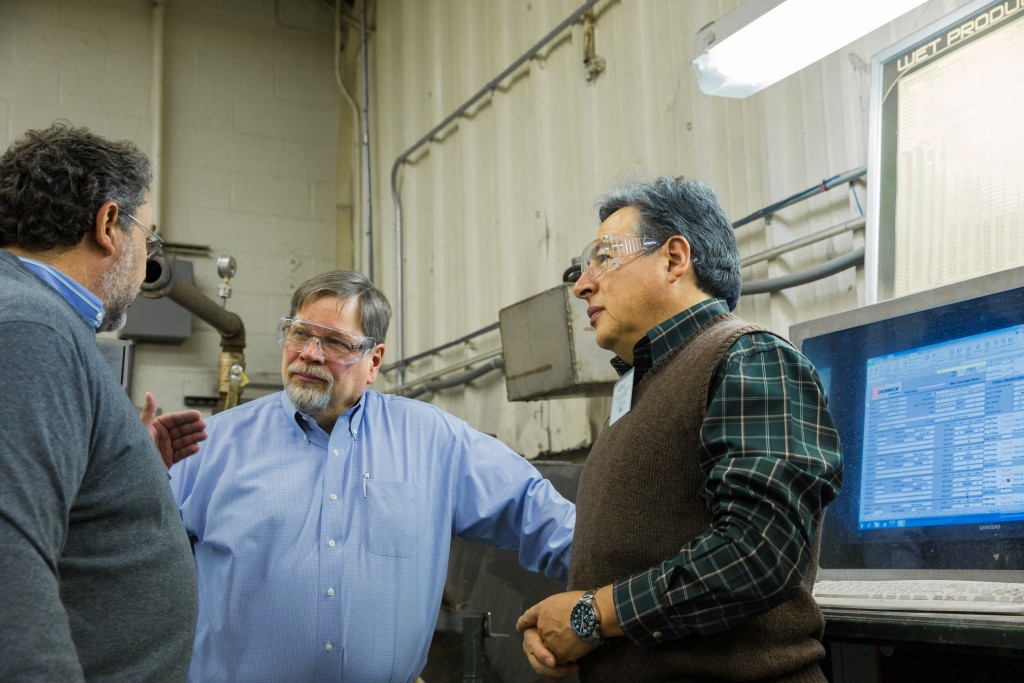

TESTING FACILITY

For over 60 years, Derrick’s Testing Facility has offered comprehensive testing and thorough reporting. By way of a dedicated and fully equipped facility, the lab permits complete testing of both wet and dry samples under actual field conditions, on full size machines. The Derrick testing facility is an integral part of the applications process. There is no better way to determine machine performance than with the actual process material. It is invaluable for customer application efforts.

The Process

- Step 1: Customer contacts Derrick to relay interest in setting up laboratory tests in the testing facility

- Step 2: Derrick reaches out to the customer to gather additional required data to determine the correct Derrick equipment, number of machines, and recommended screen panels needed for fine-separation efficiency

- Step 3: The Derrick application engineer arranges client’s sample shipment to our Buffalo, New York testing laboratory

- Step 4: The testing facility is prepped and laboratory tests are run

- Step 5: After running the tests, Derrick provides the customer with a comprehensive test report that includes an explanation of all testing methods and procedures, along with a size distribution, flow diagram depicting the feed characteristics, as well as quantities and percentages of the undersize and oversize materials

Exclusive Benefits

- Leveraging actual materials is the only reliable way to determine process performance

- Computer modeling cannot account for particle variations like shape, density, and slurry viscosity due to the fact that every sample is different

- Depending on the origin of the sample, some particles may be needle-like, while others more spherical still others thin and flat

- Variations in sample size cause the materials to screen differently

- Computer modeling cannot account for particle variations like shape, density, and slurry viscosity due to the fact that every sample is different

- Derrick applies state of the art equipment to perform tests

- Magnetic flow meters accurate to 1% of the flow rate

- Automated control valves to maintain steady flow rates

- Automated weigh belt feeders for feed control to dry equipment

- Each test is videotaped to document test programs

- Visiting Derrick testing laboratory allows full viability of Derrick’s quality commitment

- Typically, test service is provided at no additional cost to the customer

Interested in Running Laboratory Tests in our Testing Facility?

Click the button below to contact us.