Your All-in-One Solution SUPERSTACK SUPERSTACK

Click each Callout for more details

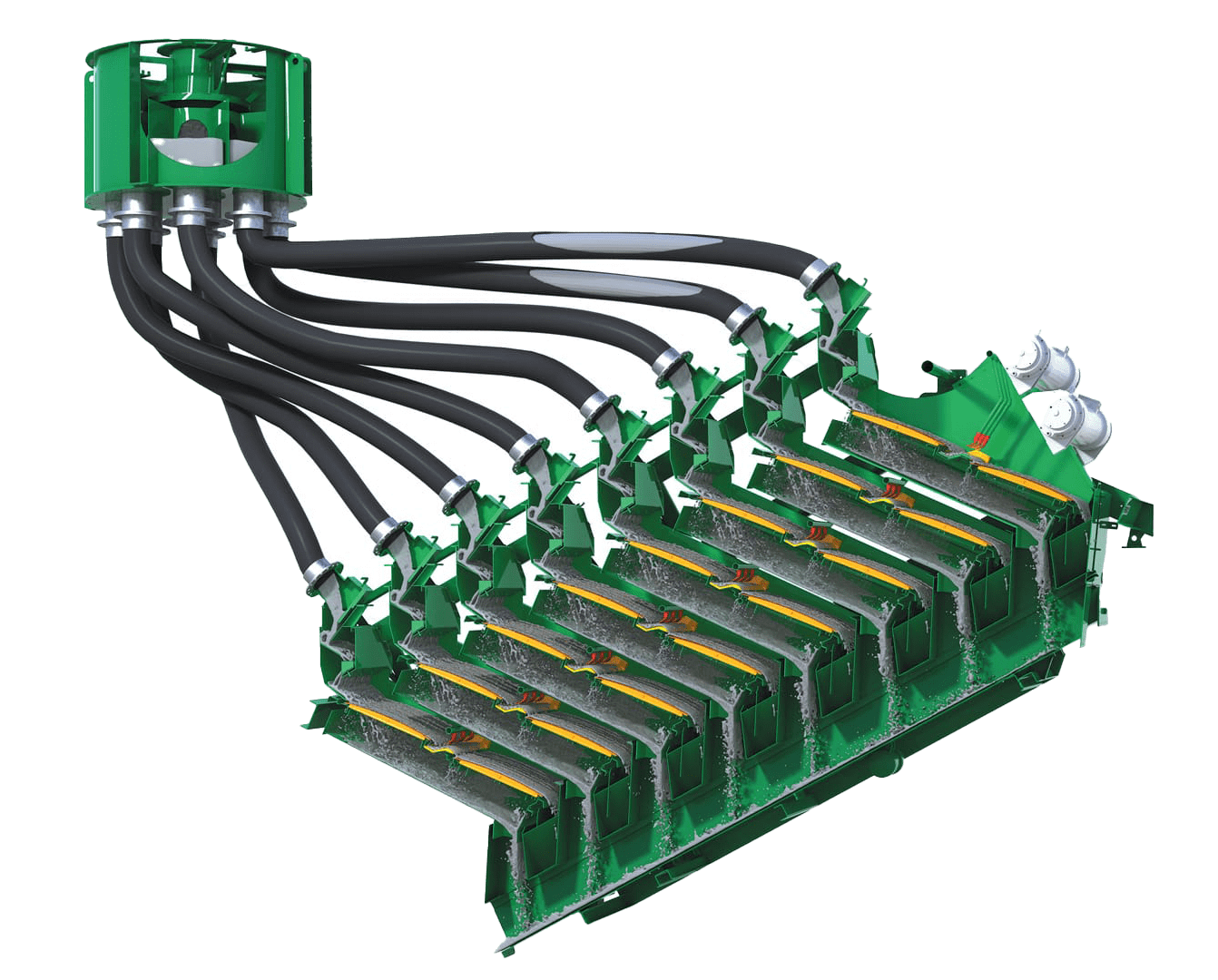

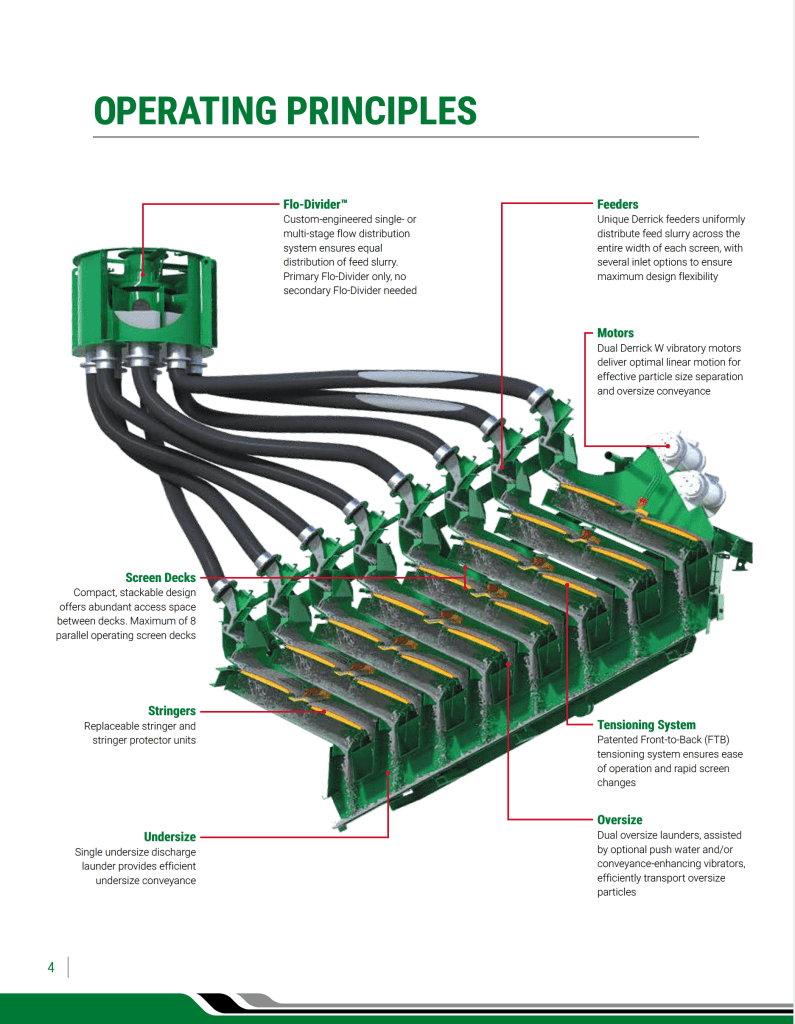

Flo-Divider™

Custom-engineered single- or multi-stage flow distribution system ensures equal distribution of feed slurry. Primary Flo-Divider only, no secondary Flo-Divider needed

Motors

Dual Derrick W vibratory motors deliver optimal linear motion for effective particle size separation and oversize conveyance

Feeders

Unique Derrick feeders uniformly distribute feed slurry across the entire width of each screen, with several inlet options to ensure maximum design flexibility

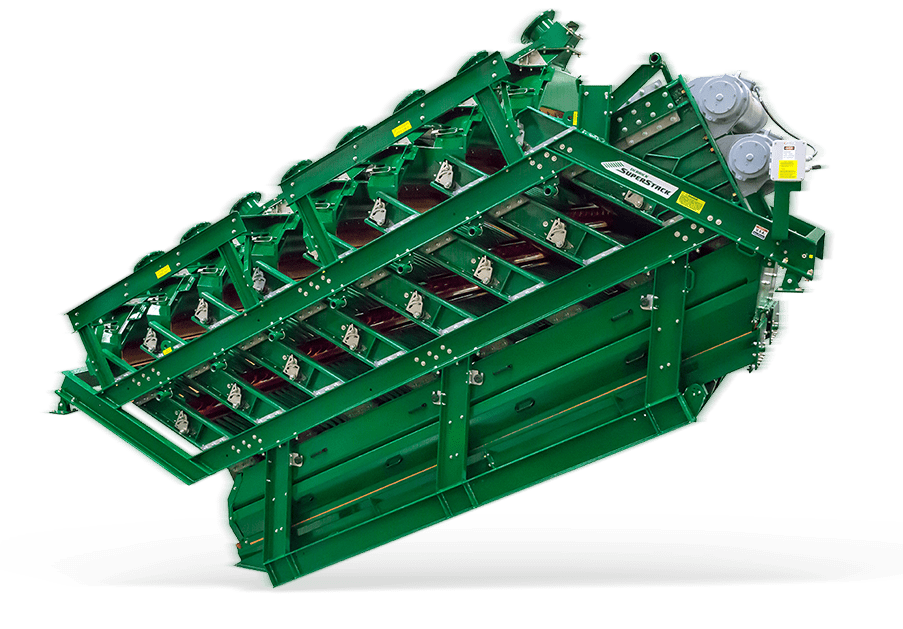

Screen Decks

Compact, stackable design offers abundant access space between decks. Maximum of 8 parallel operating screen decks

Stringers

Replaceable stringer and stringer protector units

Undersize

Single undersize discharge launder provides efficient undersize conveyance

Oversize

Dual oversize launders, assisted by optional push water and/or conveyance-enhancing vibrators, efficiently transport oversize particles

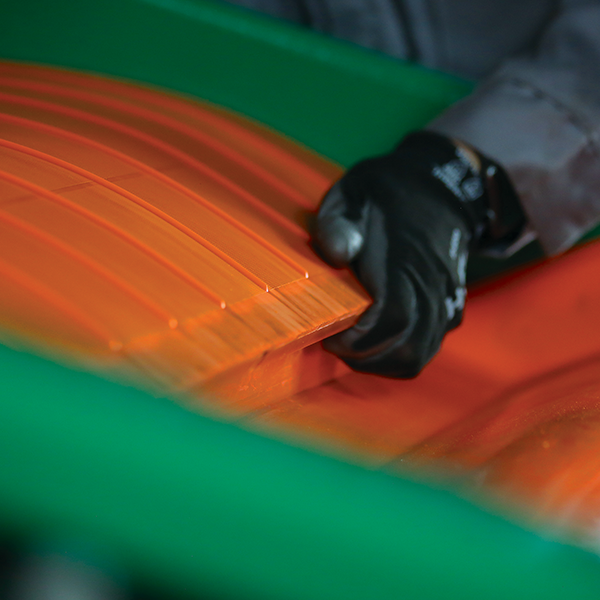

Tensioning System

Patented Front-to-Back (FTB) tensioning system ensures ease of operation and rapid screen changes

SuperStack

Features & Benefits

Industry-Leading Technology and Support

- The world leader in fine screening innovations

- Highest capacity fine screen, up to 3 times the capacity of the best fine screens currently available

- Global team with hundreds of years’ experience

- Award-wining technical support available 24 / 7

- State-of-the-art test laboratory with full scale equipment

Health, Safety, and Environment (HSE)

- Totally enclosed, lubricated-for-life vibratory motors

- Low power consumption (5kW/h)

- Lightweight, easy to install screen panels

- Exceptionally low maintenance (<1 minute per screen panel change)

- Maximize efficiency in resources recovery

Low Total Cost of Ownership

- Proven lower OPEX

- Low equivalent annual capital cost

- Minimal structural requirements due to smaller footprint at high capacities

Rapid Return on Investment

- Improve product recovery

- Maximize plant capacity

- Increase product grade and value