Gold Processing Solutions

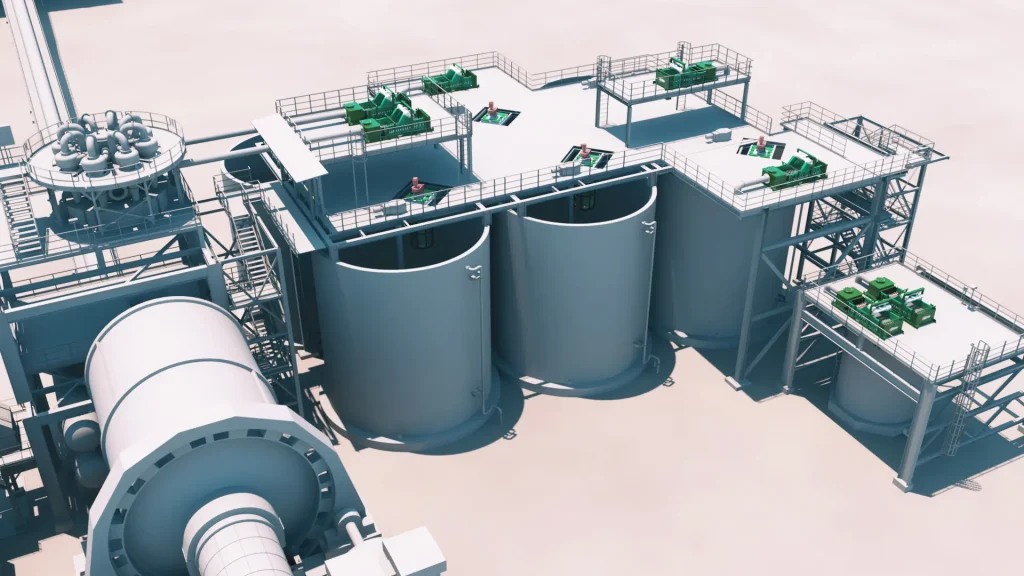

Derrick Gold Processing Solutions for CIL/CIP Circuits

Derrick continues to develop new, innovative, high capacity screening equipment to advance gold processing. Our efforts focus on reducing operational expenditure (OPEX), development of new patented technologies, and minimizing maintenance and footprint to reduce environmental impact. All of which contribute to a favorable return on investment (ROI).

These solutions include trash screens, urethane interstage screens, carbon sizing screens, dewatering screens, tails safety screens, and other processing stages.

Want to Recover More Gold?

Derrick has your complete gold processing solution.

Watch the animation below!

Derrick Application Solutions

in Gold Processing Carbon in Leach (CIL/CIP) Circuits

Watch the Trilogy Screen in Action

Dual Pool 800 Series CIP & RIP Applications