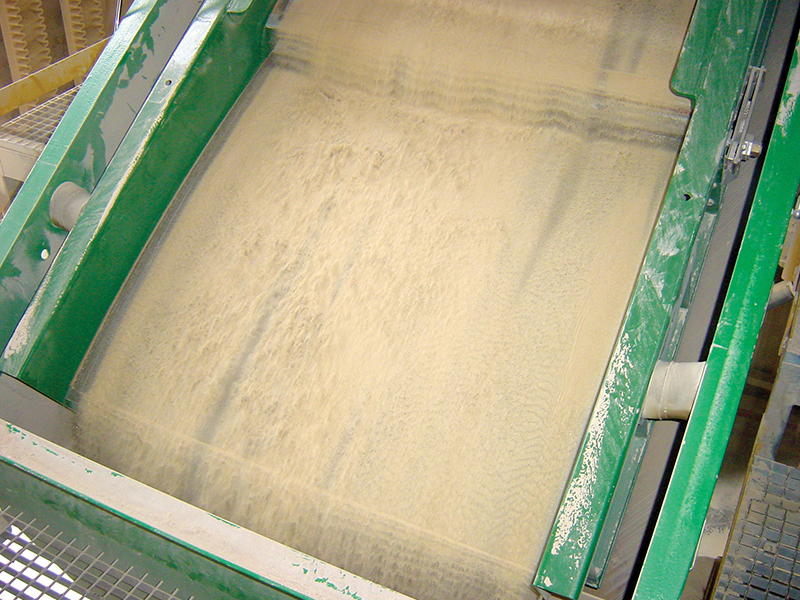

Offering the most innovative hardware available in dry screening equipment, Derrick proudly introduces the latest in dry screening technology, the Front-To-Back™ (FTB™) screen tensioning system. Increased capacity, improved efficiency, and extremely fast panel changes are all features of Derrick’s new FTB tensioning system.