Clean Mud. Green Mud. DUAL POOL DUAL POOL

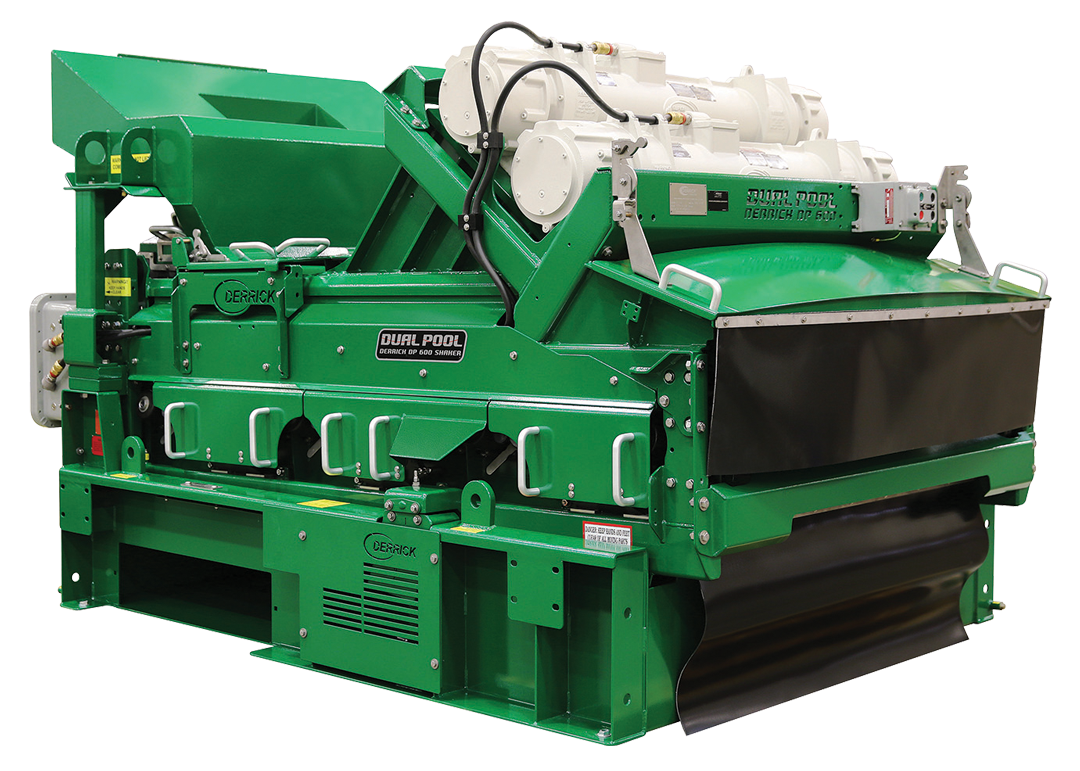

Dual Pool® 600 Series

Derrick’s knowledgeable workforce incorporates the importance of rig personnel safety and drilling optimization into every aspect of the design, manufacturing, and support of the Dual Pool® 600 Series shaker. As a result, rigs have longer uptime and employees are safe in their working environment.

- Health, Safety, & Environment (HSE)

- Dual Concave Screen Bed

- Super G3™ Integrated Vibratory Motors

- Optional Scalping Deck

- Hydraulic Screen Angle Adjustment

- Mud Cleaner Option

With a history of innovation and setting new standards, Derrick and its patented DP 600 Series shaker reassures its commitment to the drilling industry by providing long-life equipment with low maintenance requirements. This premium product includes an innovative dual concave screen frame, actuated screen compression system, optional vapor extraction covers and hood, and an optional scalping deck. The combination of these features ensures increased fluid handling capacity and provide a new standard in screening equipment.

Dual Pool Series

Features & Benefits

Health, Safety, & Environment

- Easy screen inspection, removal, and installation

- Low sound production (74 +/- 4 dBA)

- Optional vapor extraction covers and hood protect operating personnel and surrounding equipment from vapors emitted during the screening process (dependent on customer provided HVAC exhaust system)

- Optional self-locking splash hoods provide clean operating environment

- Light-weight screen panels make for easy installation

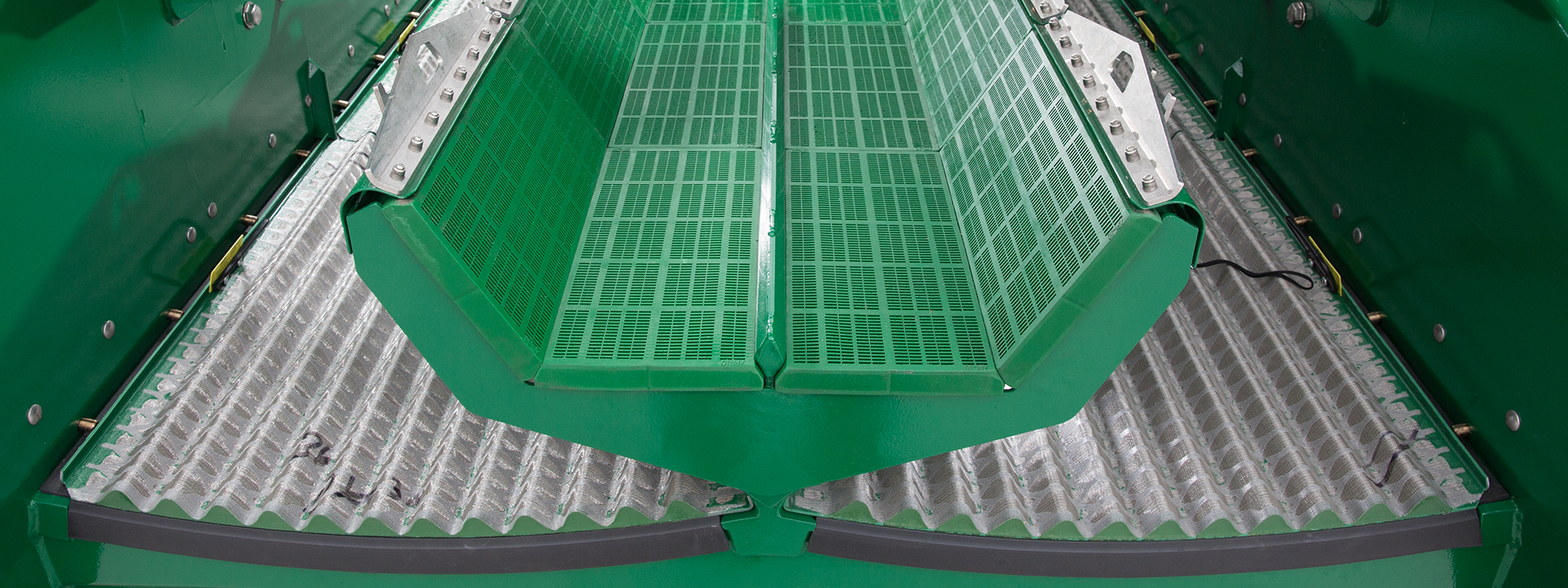

Dual Concave Screen Bed

- Fluid centering technology increases capacity

- Increased efficiency in a smaller footprint

- Compression fit bed material requires no hardware

Actuated Screen Compression System

- Eliminates bypass of solids under screen panels

- Air actuation offers quick, easy screen changes

- Fail-safe spring system securely retains panels upon loss of air pressure

- All stainless steel pneumatic fittings

- Snap-on protective covers

Super G3 Integrated Vibratory Motors

- Zero maintenance

- Industry-leading performance

- Patented continuous internal oil recirculating lubrication system

- Superior conveyance

- Three-year warranty

Optional Scalping Deck

- Effective removal of coarse material

- Optional Loss Circulation Material (LCM) reclamation

- Full view exposure of lower deck while operating

- Lower deck screen changes without removing scalping panels

- Integral bypass diverts flow directly to primary deck if desired

- Abrasion-resistant ultra-long-life urethane panels

- Stainless steel scalping deck is provided for CE/ATEX machines

Hydraulic Screen Angle Adjustment

- Adjustable screen angle while drilling from +2° to +8° for optimum capacity, screen life, and efficiency

- Manual single point system allows one man operation and optimization while drilling

Mud Cleaner

- Up to twenty 4” hydrocyclones (1600 GPM)

- Up to three 10” hydrocyclones (1500 GPM)

- Optional individual shutoff valve for each 4″ hydrocyclone

Featured

Documents

Field Report 166

Dual Pool 626 shale shakers delivered a step change in drilling performance for an offshore rig in South East Asia

- ROP improved by 41% over 19,000 meters drilled

- Drilling time reduced by 186 hours

- Resulted in net cost savings of $837,500

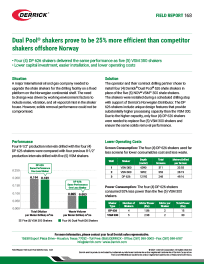

Field Report 168

Dual Pool 626 shakers prove to be 25% more efficient than competitor shakers offshore Norway

- Four (4) DP 626 shakers delivered the same performance as five (5) VSM 300 shakers

- Lower capital investment, easier installation, and lower operating costs

Field Report 176

Dual Pool 626 Shale Shaker Fleet Delivers Superior Performance Offshore Thailand

- Data driven analysis from 194 wells drilled by 9 rigs over a 10-month period.

- Rigs with Derrick Dual Pool® 626 shakers required 34% less base oil addition.

- Rigs with Derrick Dual Pool® 626 shakers used 36% fewer screens per 1500m drilled.

Discover More About the

Dual Pool Series Shaker

Contact a Derrick representative for more information!