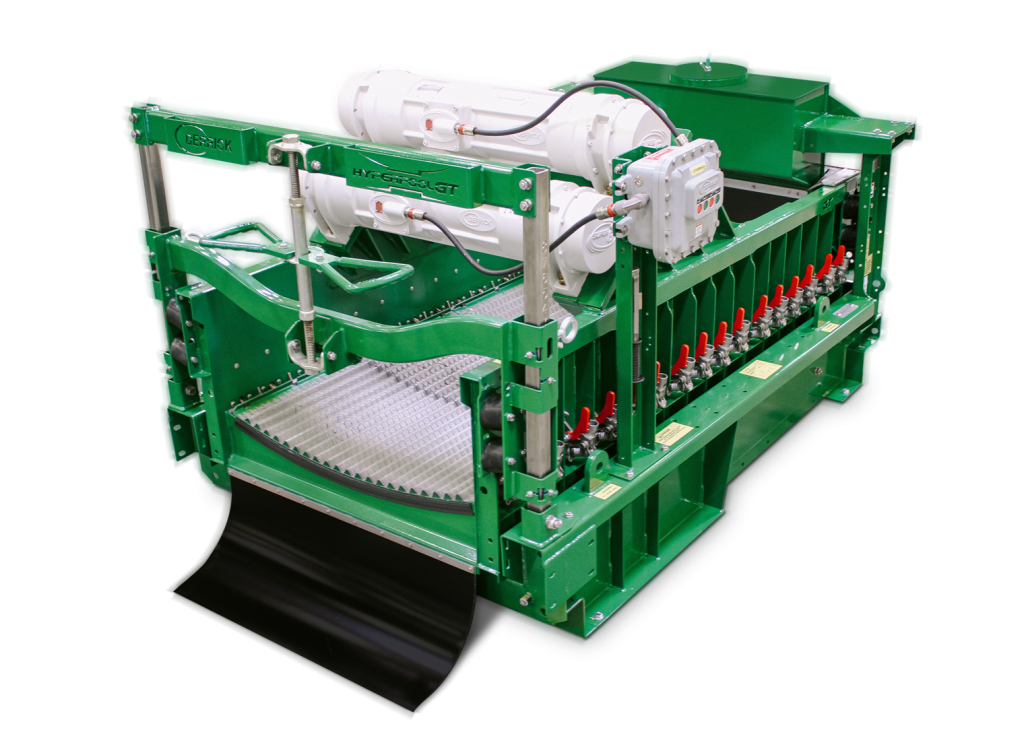

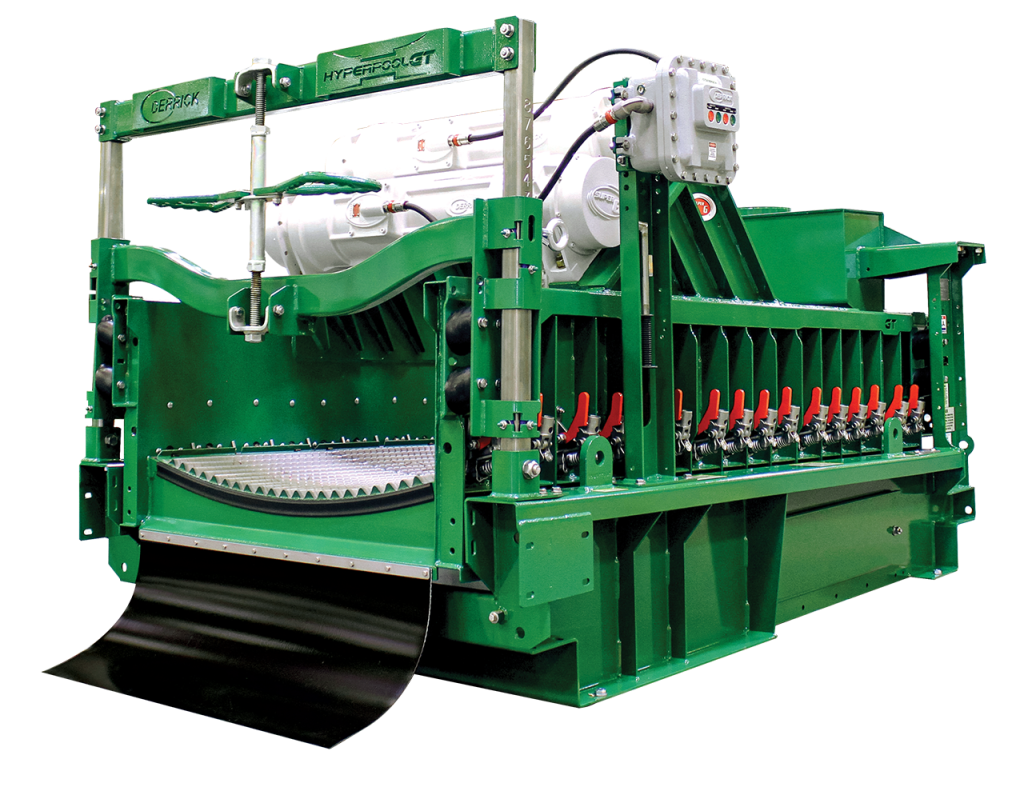

The Hyperpool® GT processes more tons per hour than any shaker on the market. Built on Derrick’s trusted Hyperpool® platform, Hyperpool GT combines proven reliability with next-generation improvements. It delivers up to a 22% increase in total handling capacity, streamlined maintenance, and plug-and-play installation options. The Hyperpool GT is engineered for the demands of today’s fast-paced, high-solids drilling and ready to power the screening technology of tomorrow. Backed by the reliability and support Derrick is known for, the Hyperpool GT gives operators and drilling contractors a low-risk path to higher efficiency and consistent, reliable results.

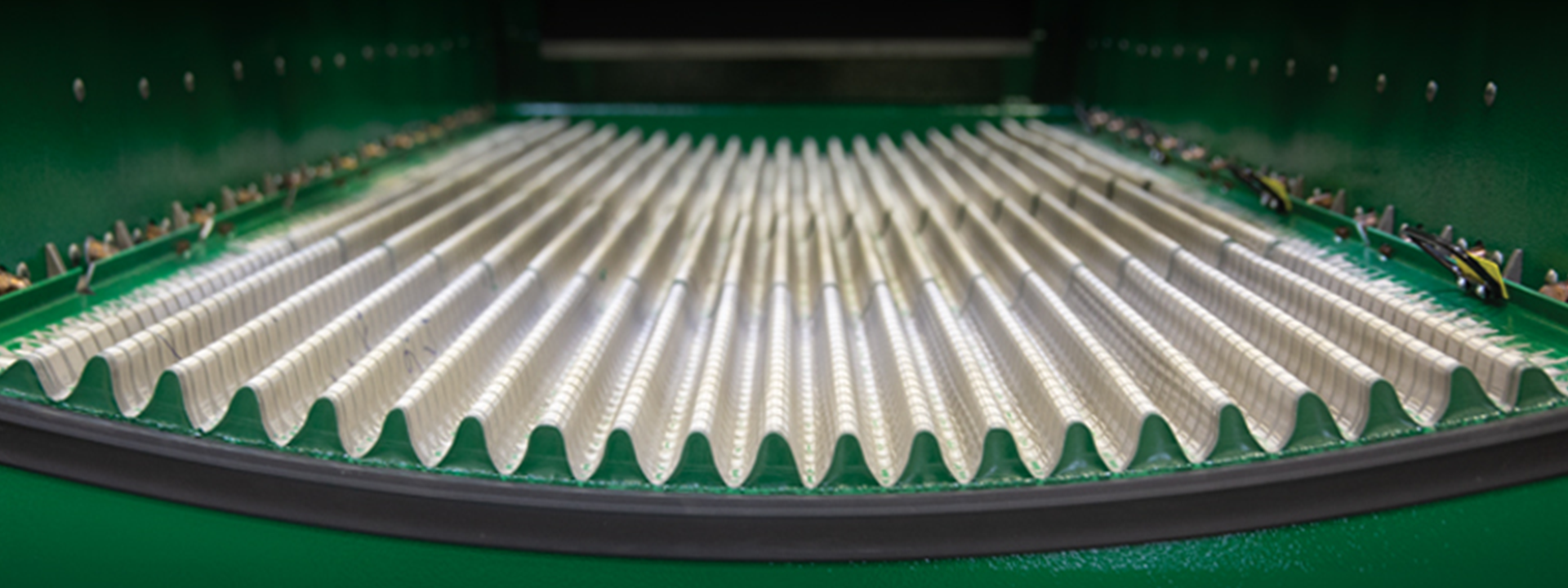

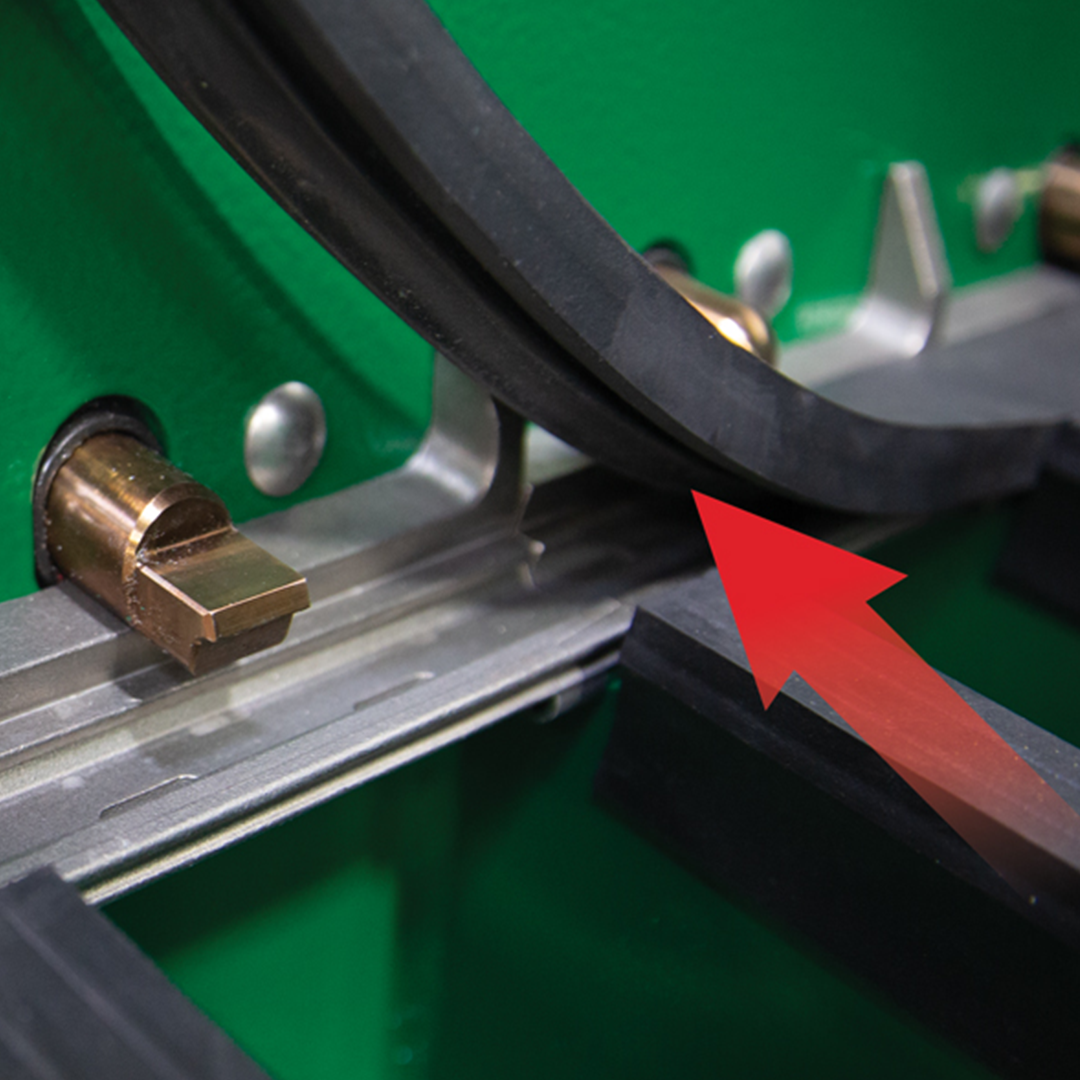

The Hyperpool GT, while retaining the trusted screen frame design of the original Hyperpool, has incorporated over a decade of refinements. These include increased flow handling and capacity, interlocking compression technology, and a redesigned shaker bed. Most importantly, its vibrating screen frame maintains the same footprint and underflow hopper as the original Hyperpool, ensuring a seamless transition for users. Additionally, the Hyperpool GT can operate as a stand-alone unit and is compatible with K-Series, M-Series and FLC 503 upgrade kits.

Delivering Higher Efficiency & Lower Costs In The Colorado DJ Basin

Delivering Higher Capacity & Lower Drilling Costs in the New Mexico Delaware Basin